Top Ball Valve Manufacturers of 2026 What to Look For?

The world of ball valve manufacturers is evolving rapidly. As industries demand more efficient solutions, the focus on quality and innovation intensifies. The year 2026 promises significant developments, making it essential for buyers to understand what to look for in these manufacturers.

When selecting ball valve manufacturers, buyers should prioritize reliability and technological advancements. A manufacturer’s reputation can often determine the quality of the valves. Customers should also consider factors like customer service and support. Good communication is as important as product quality.

Innovative features can set manufacturers apart in a crowded market. Energy efficiency and durability are crucial buying factors. However, not every manufacturer meets high standards, leading to dissatisfaction. So, it’s vital to research and reflect on past experiences. By examining these aspects, buyers can make informed decisions and find the right ball valve manufacturers for their needs.

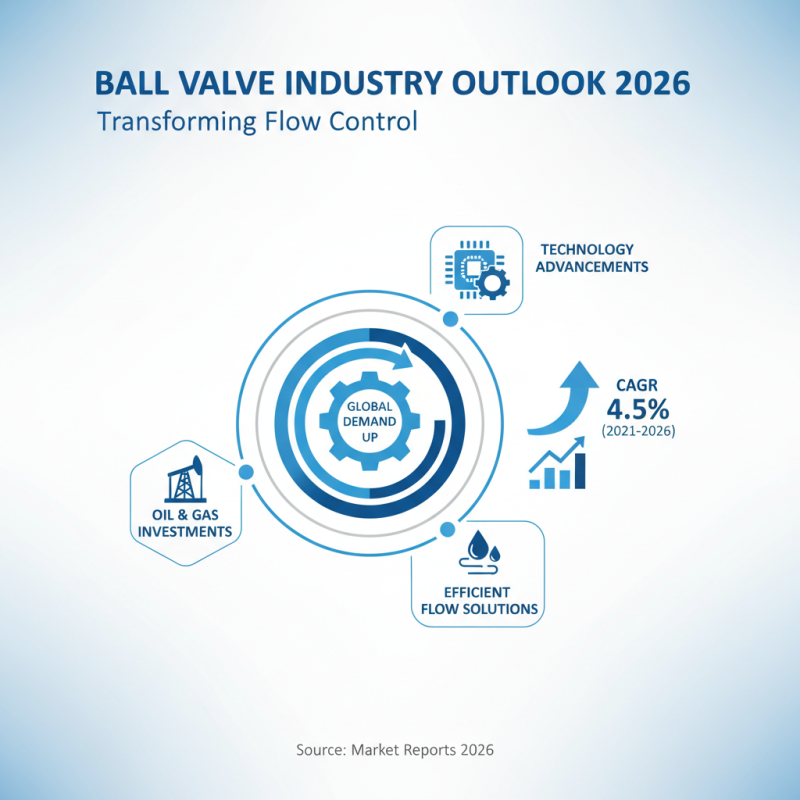

Overview of the Ball Valve Industry Trends for 2026

The ball valve industry is witnessing significant changes as we approach 2026. An increase in global demand for efficient flow control solutions is evident. According to recent market reports, the ball valve market is projected to grow at a CAGR of 4.5% between 2021 and 2026. This growth is driven by advancements in technology and rising investments in the oil and gas sector.

Environmental concerns are shaping the industry. Companies are under pressure to develop more sustainable products. Many are exploring new materials and designs that reduce the environmental impact. A notable trend is the incorporation of smart technologies. This allows for better monitoring and control, enhancing operational efficiency. However, the adoption of such technologies can be slow due to high initial costs and the need for skilled technicians.

Market competition is also intensifying. Manufacturers face challenges in maintaining quality while keeping costs low. Failure to adapt can lead to a loss of market share. There’s a need for continuous innovation in product design and process optimization. Balancing cost, performance, and sustainability is crucial. The future holds promise, but companies must be prepared for the evolving demands of the market.

Key Specifications and Standards for Quality Ball Valves

When considering ball valves, key specifications are crucial for quality. Material selection plays an important role in durability. Common materials include brass, stainless steel, and PVC. The choice can greatly impact performance. Look for valves designed to handle specific pressures and temperatures. Misunderstanding these parameters can lead to failures.

Another vital aspect is the valve design. A full-port design allows for smoother flow, reducing pressure drops. Conversely, reduced-port valves may fit tighter spaces but could impair efficiency. Ensure that the valve's end connections match your piping system. Compatibility is essential to avoid leaks.

Standards also play a significant role in ensuring quality. ISO and ANSI specifications set benchmarks for performance. Manufacturers should provide clear documentation of compliance. Lack of transparency might raise concerns regarding the valve's reliability. Always double-check these standards to avoid future issues. Make informed decisions for long-lasting solutions.

Top Ball Valve Manufacturers of 2026 - Key Specifications and Standards for Quality Ball Valves

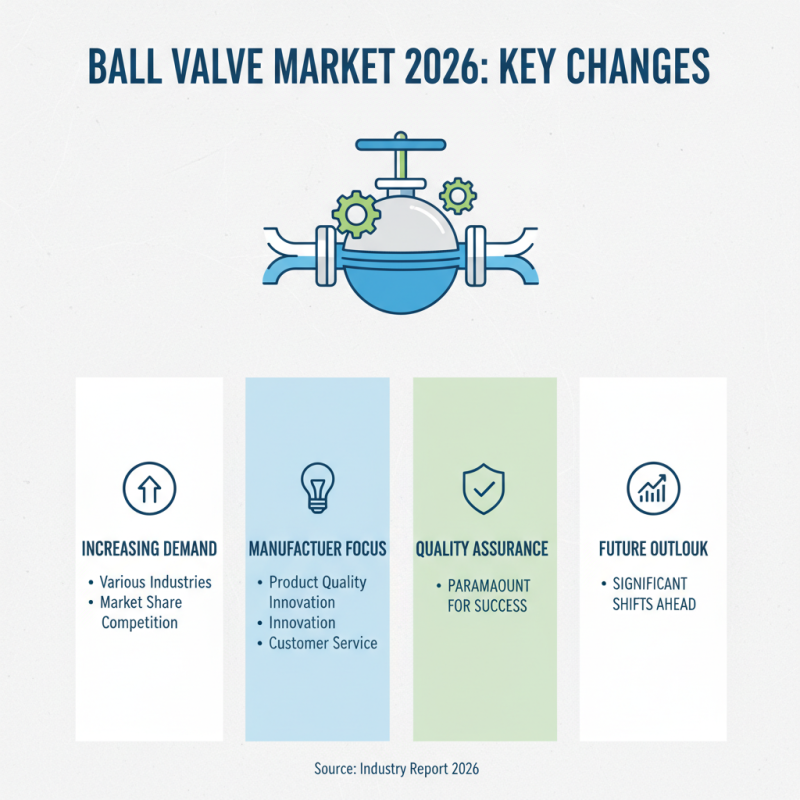

Analysis of Market Share Among Top Ball Valve Manufacturers

In 2026, the ball valve market is set for significant changes. With increasing demand across various industries, manufacturers vie for market share. Key factors to consider include product quality, innovation, and customer service. Quality assurance processes will remain paramount for long-term success.

Many manufacturers are streamlining operations, aiming for efficiency. This can lead to cost reductions but may impact quality if not managed properly. Customers value durability and reliability. A focus solely on cutting costs could backfire.

Emerging technologies are changing the landscape. Smart valves with real-time monitoring will gain traction. However, integrating these advancements poses challenges for traditional manufacturers. They must adapt quickly or risk losing their competitive edge. Understanding market dynamics is crucial for sustainability in this evolving environment.

Emerging Technologies in Ball Valve Design and Manufacturing

The landscape of ball valve design and manufacturing is shifting. Emerging technologies are transforming how these essential components are made. New materials are being used to enhance durability and resistance to corrosion. For instance, advanced polymers are now common, improving performance in harsh environments.

Automation plays a pivotal role in modern manufacturing processes. Robotics can achieve precise machining that was once impossible. However, reliance on automation may lead to a loss of traditional craftsmanship. This shift requires manufacturers to balance technology with skilled labor.

Moreover, digital tools are shaping design protocols. 3D modeling and simulation software allow for rapid prototyping. Yet, this rapid pace may overlook the importance of thorough testing. The pressure to innovate quickly often results in overlooked details that can affect quality. Reflecting on these challenges is necessary to ensure the future of ball valve manufacturing remains strong and effective.

Sustainability Practices Adopted by Leading Ball Valve Companies

In 2026, sustainability is paramount for ball valve manufacturers. Many leading companies are embracing eco-friendly practices. They invest in materials that reduce environmental impact. Recycled metals and sustainable polymers are becoming common. This shift is essential as industries face increasing pressure to minimize waste.

Energy-efficient production processes are on the rise. Some manufacturers are exploring renewable energy sources. Solar and wind power help decrease carbon footprints. However, not all companies are fully committed. Some still rely on outdated methods. This inconsistency highlights a need for improvement.

Waste management is another focus area. Innovative recycling programs are being developed. Many companies aim for zero waste in operations. Yet, achieving this goal remains challenging. Some struggle to track waste effectively. As industries evolve, the push for better practices continues to grow.

Top Ball Valve Manufacturers of 2026 - Sustainability Practices Adopted by Leading Ball Valve Companies

| Manufacturer | Year Established | Sustainability Initiatives | Recycled Materials Used (%) | Energy Efficiency Rating |

|---|---|---|---|---|

| Manufacturer A | 1998 | Solar panel installation, zero-waste policy | 30% | A+ |

| Manufacturer B | 2002 | Carbon-neutral production, eco-friendly packaging | 25% | A |

| Manufacturer C | 1985 | Water conservation programs, renewable energy usage | 40% | A++ |

| Manufacturer D | 2010 | Biodegradable materials, green supply chain | 20% | B+ |

Related Posts

-

Exploring the Innovations and Technologies Shaping the Future of Ball Valve Manufacturers

-

Top 10 Types of Valves: Unlocking Key Insights for Industrial Efficiency

-

What is the Best Valve Tag for 2026?

-

2026 Best Stainless Steel Solenoid Valve Options for Your Needs?

-

How to Choose the Right Control Valve for Your Industrial Applications

-

How to Choose the Right Flow Control Valve for Your Application Needs