Top 10 Cryogenic Ball Valves You Should Know About?

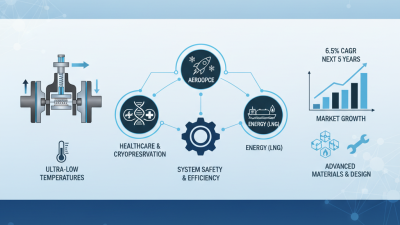

In the realm of industrial applications, cryogenic ball valves play a critical role. These valves are essential for controlling the flow of fluids at extremely low temperatures. According to a report by Global Market Insights, the cryogenic valve market is projected to reach over $2 billion by 2026, driven by increasing demand in the oil and gas sector.

Dr. Emily Hart, a leading expert in cryogenic systems, once stated, "The efficiency and reliability of cryogenic ball valves can significantly impact operational success in harsh environments." This highlights their importance in maintaining safety and efficiency in industries like LNG and aerospace. However, as technology advances, there are challenges regarding maintenance and lifecycle management, which companies must address.

Understanding the top 10 cryogenic ball valves is vital for industry professionals. Each valve offers unique features and specifications tailored for distinct applications. With fluctuating market demands, knowing the best options available is essential for making informed decisions. Failure to choose the right valve can lead to delays and increased costs. Therefore, assessing these critical components can enhance operational performance in cold temperature processes.

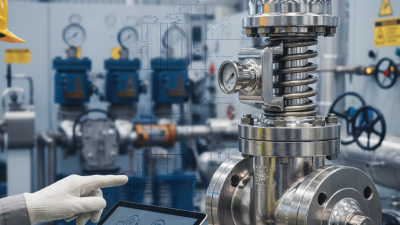

Overview of Cryogenic Ball Valves and Their Applications

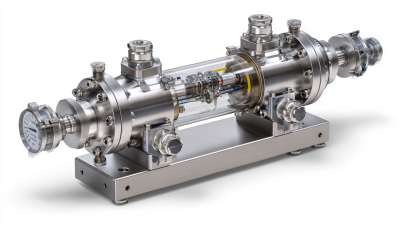

Cryogenic ball valves play a vital role in various industries, such as liquid natural gas (LNG) and aerospace. These valves are designed to operate in extremely low temperatures, often below -196°C. The ability to maintain a reliable seal is crucial in these environments. According to a recent industry report, cryogenic valves can reduce leakage rates by up to 90% compared to traditional valves.

The material composition of cryogenic ball valves is essential for their performance. Common materials include stainless steel and specialized alloys. These materials endure the rigors of low-temperature operations while ensuring durability. Interestingly, not all valves perform equally well under stress. Manufacturers have found that some designs fail to meet safety standards, which can lead to costly leaks and operational downtime.

Cryogenic applications are not without challenges. For instance, the installation process can be complex. Proper training is essential for technicians to mitigate misalignment or installation errors. Furthermore, maintenance requires careful attention due to potential thermal expansion issues. Adequate training and safety protocols are necessary to prevent equipment failures. Regular inspections are equally important to ensure long-term efficiency and reliability in critical operations.

Top 10 Cryogenic Ball Valves You Should Know About

| Valve Type | Material | Temperature Range (°C) | Pressure Rating (bar) | Applications |

|---|---|---|---|---|

| Floating Ball Valve | Stainless Steel | -200 to 70 | 40 | Cryogenic liquids, LNG |

| Trunnion Mounted Ball Valve | Carbon Steel | -196 to 100 | 60 | LNG, hydrogen |

| Full Port Ball Valve | Copper Alloy | -196 to 80 | 50 | Cryogenic services |

| Reduced Bore Ball Valve | Stainless Steel | -200 to 100 | 40 | Natural gas, LNG |

| High Pressure Ball Valve | Alloy Steel | -200 to 60 | 100 | LNG, industrial gases |

| Cryogenic Safety Valve | Stainless Steel | -196 to 70 | 16 | Safety applications |

| Electric Actuated Ball Valve | Carbon Steel | -196 to 100 | 40 | Automated systems |

| Manual Operated Ball Valve | Bronze | -200 to 60 | 40 | Gas handling |

| Two-Piece Ball Valve | Stainless Steel | -196 to 100 | 50 | Chemical processing |

Key Features and Specifications of Cryogenic Ball Valves

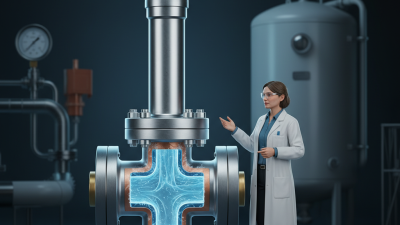

Cryogenic ball valves are essential in handling low-temperature fluids. These valves are designed to perform efficiently in extreme conditions. Their primary function is to control flow in applications involving liquefied gases like LNG or nitrogen. The specification of materials is critical. Commonly, stainless steel and special alloys are utilized for durability. This enhances their reliability under severe temperature variations.

Key features of these valves include their ability to operate at temperatures below -200°C. They come with a special sealing mechanism that prevents leaks. Many valves are designed for easy installation and maintenance. They often feature a compact body design that saves space. Surprisingly, not all products meet performance expectations. Some valves may experience leakage or operational failure over time. Industry reports from the American Society of Mechanical Engineers highlight that a significant number of cryogenic valve failures occur within the first few years of operation.

It's intriguing to note that pressure ratings also play a vital role in valve selection. The industry standard is often between 150 to 600 PSI. Yet, achieving optimal performance can be challenging. Some users overlook the importance of compatibility with specific cryogenic media. This can lead to performance issues or valve malfunction. Understanding the key features and specifications allows for better decision-making. In this sector, even small miscalculations can have significant consequences.

Top 10 Cryogenic Ball Valves: Performance and Reliability Comparison

When evaluating cryogenic ball valves, performance and reliability are crucial. These valves operate in extreme temperatures, making durability a priority. Depending on the specific application, materials may vary. Stainless steel and special alloys can enhance longevity and performance.

Leak tightness is another critical factor. Ensuring that valves maintain a perfect seal is essential to prevent costly failures. Some designs may struggle with this aspect, leading to safety concerns. Regular maintenance can help mitigate these issues. That's an area where reflection is necessary to improve overall efficiency.

The valve’s actuation speed also plays a role in performance. Quick actuation can be vital in emergency situations. However, some models may not respond as expected. Designers must balance speed with reliability. It's a fine line that requires careful engineering and consideration.

Installation and Maintenance Tips for Cryogenic Ball Valves

When working with cryogenic ball valves, installation is critical. Ensure that the area is clean before you begin. Contaminants can lead to serious issues. Use tools that are specifically designed for cryogenic applications. That includes wrenches and screwdrivers. Avoid using tools with excessive force. Over-tightening can damage the valve.

During maintenance, regular checks are essential. Inspect the seals and connections frequently. Look for any signs of wear and tear. If something seems off, don’t ignore it. A small leak can escalate quickly. Ensure the valve operates smoothly after every adjustment. Remember, even minor adjustments require attention. Unattended maintenance can lead to failure.

Be conscious of temperature fluctuations. They affect valve performance. If you notice unexpected temperature changes, investigate. It may indicate deeper issues. Maintenance records should be kept up to date. They help in identifying patterns and potential problems. Take note of each inspection, however minor. What may seem unimportant now could be vital later.

Future Trends in Cryogenic Ball Valve Technology and Innovations

The future of cryogenic ball valve technology is promising. Innovations are emerging rapidly. Manufacturers are exploring new materials. These materials can withstand extreme temperatures without compromising performance. For instance, carbon fiber composites show significant potential in enhancing durability.

Smart technology integration is another exciting trend. Remote monitoring and control can improve efficiency. These systems can predict maintenance needs, reducing downtime. However, the initial cost of these systems can be high. This expense may deter some companies from adopting them.

Sustainability is becoming a priority. Eco-friendly manufacturing processes are gaining traction. This shift requires rethinking traditional production methods. While the advancements are impressive, challenges remain. Ensuring reliability in varied conditions is crucial. Continuous research and development will be necessary to overcome these hurdles.

Related Posts

-

The Essential Role of Cryogenic Valves in Modern Cryogenic Systems and Their Impact on Energy Efficiency

-

Unlocking the Science Behind Cryogenic Valves: Essential Insights for Safe Operation

-

How to Choose the Right Cryogenic Valves for Your Applications

-

Best Cryogenic Check Valves for Essential Applications in Cold Environments

-

What is a Cryogenic Valve and How Does it Work?

-

How to Choose the Right Safety Valve for Your Application?