Top 10 Pressure Control Valves: Features, Benefits, and Buying Guide

When it comes to maintaining optimal fluid system performance, the significance of a reliable pressure control valve cannot be overstated. These critical components are designed to regulate pressure levels within various applications, ensuring safety, efficiency, and longevity of the systems they serve. In a world where industrial processes demand precision and reliability, understanding the features and benefits of pressure control valves becomes essential for engineers and decision-makers alike.

This article aims to explore the top 10 pressure control valves currently available on the market, highlighting their unique attributes and the advantages they bring to diverse applications. From enhanced operational safety to improved energy efficiency, a well-chosen pressure control valve can make a substantial difference in the functionality and reliability of any system. Additionally, we will provide a comprehensive buying guide to assist you in selecting the right pressure control valve that suits your specific needs, enabling you to make an informed decision that will contribute to the success of your projects.

Understanding Pressure Control Valves: Definition and Functionality

Pressure control valves are essential components in various industrial applications, designed to regulate and maintain desired pressure levels in systems. These valves function by automatically adjusting the flow of fluid or gas, ensuring that pressure remains within safe limits. When pressure exceeds set thresholds, the valve opens to release excess fluid, preventing potential damage to equipment and ensuring operational safety.

Tips for selecting the right pressure control valve include understanding the specific requirements of your system, such as maximum pressure, flow rates, and the type of fluid being handled. Look for valves with features like quick response times and adjustable settings, as these can enhance system efficiency. Additionally, always consider the material of the valve to ensure compatibility with the working environment and the substances involved.

Another important aspect to consider is the maintenance of pressure control valves. Regular inspections can help identify wear and tear, ensuring that the valve operates optimally. It is crucial to implement a routine maintenance schedule, as this not only prolongs the lifespan of the valve but also ensures the overall reliability of the system. Always consult technical documentation and ensure that the installation is performed by qualified personnel to maintain safety and performance standards.

Top 10 Pressure Control Valves: Features, Benefits, and Buying Guide

| Model | Type | Pressure Range (psi) | Material | Benefits |

|---|---|---|---|---|

| Model A | Spring-loaded | 0-150 | Stainless Steel | Compact Design, High Accuracy |

| Model B | Pilot-operated | 15-300 | Bronze | High Flow Rate, Reduced Noise |

| Model C | Diaphragm | 10-200 | Plastic | Corrosion Resistant, Lightweight |

| Model D | Ball Valve | 0-500 | Carbon Steel | Durable, Easy Maintenance |

| Model E | Pressure Regulator | 5-100 | Aluminum | Lightweight, Adjustable |

| Model F | Electronic | 0-600 | Stainless Steel | Precision Control, Automated |

| Model G | Globe Valve | 20-400 | Cast Iron | Versatile, Good Flow Control |

| Model H | Check Valve | 0-200 | Brass | Prevent Backflow, Low Maintenance |

| Model I | Pressure Relief | 10-1000 | Stainless Steel | Safety Feature, Reliable |

| Model J | Solenoid | 0-300 | Plastic | Quick Response, Remote Control |

Key Features to Consider When Selecting Pressure Control Valves

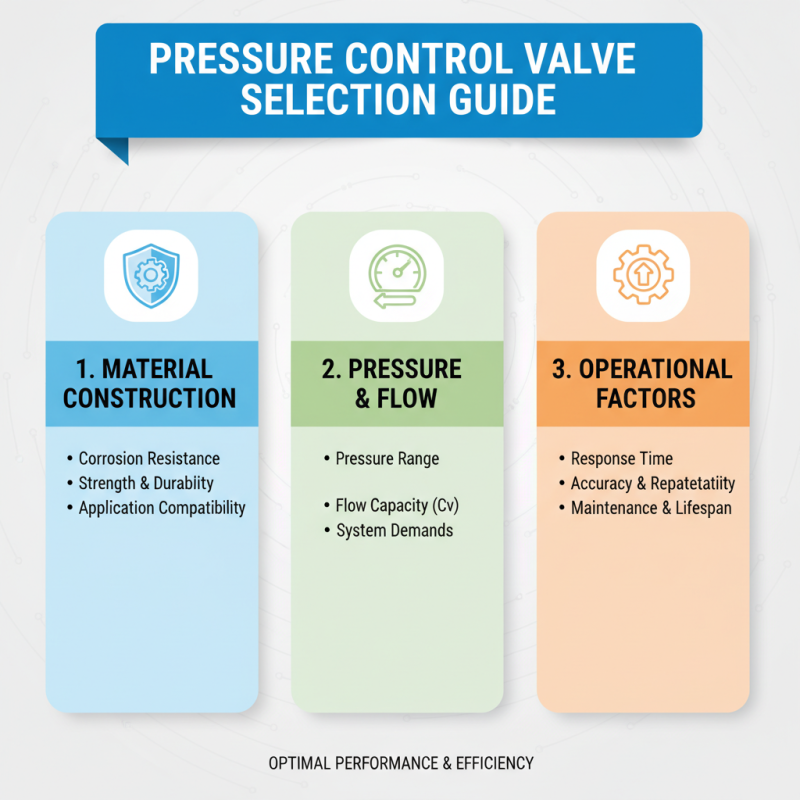

When selecting pressure control valves, several key features should be prioritized to ensure optimal performance and efficiency. First and foremost, it’s crucial to assess the valve's material construction. Different materials offer varying levels of corrosion resistance, strength, and durability, which directly affects the valve's longevity and reliability in diverse operating environments. Additionally, understanding the pressure range and flow capacity of the valve is essential, as these parameters dictate whether the valve can handle the specific demands of your application.

Another significant feature to consider is the valve’s response time and accuracy. A pressure control valve should be able to maintain precise pressure levels with minimal fluctuations to prevent system instability. Look for features such as an adjustable set point and feedback mechanisms for better control. Furthermore, the ease of installation and maintenance should not be overlooked; valves that are easier to install tend to reduce downtime and labor costs. Lastly, reviewing product certifications and compliance with industry standards can provide additional assurance of the valve's performance and safety in your application.

Benefits of Using Pressure Control Valves in Various Applications

Pressure control valves play a crucial role in maintaining optimal fluid pressure within various systems, providing numerous benefits across multiple applications. In industries such as oil and gas, water treatment, and manufacturing, these valves ensure that pressure levels remain within specified limits, thus preventing equipment damage and improving overall operational efficiency. By automatically adjusting the flow of fluids, they help mitigate risks associated with pressure fluctuations, enhancing safety and reliability in processes.

In addition to safeguarding equipment, pressure control valves also contribute to energy efficiency. By regulating the pressure and flow of fluids, these valves minimize energy consumption, which can lead to significant cost savings over time. Furthermore, their ability to maintain consistent pressure ensures that systems operate smoothly, reducing wear and tear on pumps and other components. Whether used in hydraulic systems, pneumatic applications, or irrigation setups, the implementation of pressure control valves ultimately leads to improved performance, reduced downtime, and increased longevity of machinery.

Top 10 Pressure Control Valves: A Comparative Overview

When considering pressure control valves, a comparative overview reveals critical distinctions that influence performance and efficiency. According to a recent market analysis by Research and Markets, the global pressure control valve market was valued at approximately $1.5 billion in 2022 and is projected to grow at a CAGR of 6.2% over the next five years. This growth highlights the increasing demand across various industries, including oil and gas, water and wastewater treatment, and manufacturing.

Selecting the right pressure control valve depends on understanding key features, such as the valve's design type, material compatibility, and range of pressure settings. For instance, valves made from corrosion-resistant materials can effectively handle aggressive media, while those with fine-tuning capabilities allow for precise control in critical applications. Furthermore, modular designs can simplify maintenance and replaceability, contributing to a longer lifespan and lower operational costs.

Tips: When evaluating potential pressure control valves, always assess the specific application requirements. Consider factors such as maximum and minimum pressure needs, flow characteristics, and environmental conditions. Ensuring compliance with industry standards can significantly enhance reliability. Also, don’t hesitate to consult technical datasheets to compare specifications, as these documents provide vital insights into performance metrics and operational efficiencies, ensuring you make an informed decision.

Essential Buying Guide for Pressure Control Valves: What to Look For

When selecting pressure control valves, several key features should be prioritized to ensure optimal performance and safety. Firstly, consider the valve material, which should be compatible with the specific fluid being controlled, as various materials possess different resistance to chemicals and temperature variations. The pressure range is also critical; ensure the valve can handle the maximum pressure expected in the application while providing precise control at lower levels. Additionally, look for valves equipped with adjustable settings, enabling customization tailored to specific operational requirements.

Another essential aspect is the valve design, which can significantly affect functionality and maintenance needs. Choose valves that offer easy access for servicing and repairs, as well as those that are compact and lightweight for easier installation. Consider the actuator type—whether manual or automatic—depending on your needs for efficiency and automation. Lastly, verifying certifications and compliance with relevant industry standards is crucial to ensure the valve meets safety and quality benchmarks, which ultimately helps in avoiding costly downtime and accidents in operational environments.

Top 10 Pressure Control Valves: Features and Benefits

This chart illustrates the pressure handling capacity of the top 10 pressure control valves. As shown, each valve is rated for a different maximum pressure, which is essential for determining their suitability for various applications.

Related Posts

-

Understanding the Essential Role of Pressure Vacuum Valves in Modern Industrial Systems

-

Understanding the Importance of Relief Valves in Modern Industrial Applications

-

What is a Pressure Control Valve and How Does It Work in Different Applications

-

Exploring the Innovations and Technologies Shaping the Future of Ball Valve Manufacturers

-

Essential Guide to Understanding High Pressure Relief Valves: How They Ensure Safety in Industrial Applications

-

How to Choose the Right Control Valve for Your Industrial Applications