Understanding the Key Benefits of Using Ball Valves in Modern Plumbing Systems

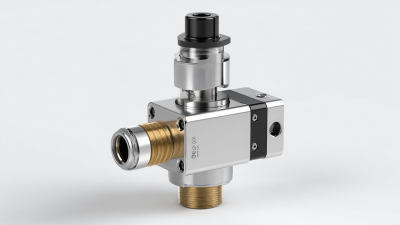

In modern plumbing systems, the choice of valves can significantly impact efficiency, reliability, and maintenance. One of the most preferred options among professionals and homeowners alike is the ball valve, renowned for its superior performance in controlling the flow of liquids and gases. The ball valve operates using a spherical disc, which allows for quick and precise regulation, making it ideal for a variety of plumbing applications.

Its construction typically features durable materials that withstand high pressure and temperature, leading to a considerably longer lifespan compared to other valve types. Furthermore, ball valves offer minimal flow resistance and can be easily operated, either manually or automatically, contributing to their growing popularity in both residential and industrial settings. This article aims to delve into the key benefits of using ball valves, elucidating their importance in modern plumbing systems and why they have become a staple choice for efficient fluid control.

Key Advantages of Ball Valves in Plumbing Applications

Ball valves are increasingly favored in modern plumbing systems due to their numerous advantages. One of the key benefits is their ability to provide a tight seal, which helps prevent leaks. According to a report by the American Society of Plumbing Engineers, ball valves can achieve a leak-proof seal even under high pressure, making them suitable for various applications including water supply systems, gas lines, and chemical handling. This reliability not only enhances safety but also reduces maintenance costs associated with leaks and water wastage.

Another significant advantage of ball valves is their ease of operation. With a simple quarter-turn mechanism, they can quickly turn on or off the flow of fluids. Research from the Plumbing & Mechanical Professionals Association indicates that this characteristic minimizes the risk of human error during operation, which is critical in both residential and commercial plumbing applications. Additionally, ball valves have a longer lifespan compared to other valve types, with many designed to endure over 50,000 cycles without failure, making them a cost-effective choice in the long run. These features underline the growing preference for ball valves in today’s plumbing strategies.

Enhanced Flow Control: Reasons to Choose Ball Valves

Ball valves are increasingly favored in modern plumbing systems due to their exceptional flow control capabilities. Unlike other valve types, ball valves use a spherical disc to regulate flow, which allows for quick and easy adjustments. This feature not only enhances efficiency but also minimizes the risk of leaks, making them ideal for both residential and industrial applications. Their simple quarter-turn operation ensures that users can achieve full flow or complete shut-off effectively.

When choosing ball valves, consider these tips for optimal performance: first, always select the right size and pressure rating to fit your plumbing system’s requirements. Underestimating these factors can lead to inadequate flow control or system failures. Secondly, using high-quality materials, such as stainless steel or brass, can significantly prolong the lifespan of your valves. Finally, regular maintenance checks can help identify potential issues before they escalate, ensuring the continued reliability of your plumbing system.

Overall, ball valves stand out not only for their ease of use but also for their capacity to provide precise flow regulation, making them an excellent choice for anyone looking to enhance their plumbing infrastructure.

Durability and Longevity: Why Ball Valves Outperform Alternatives

Ball valves have emerged as the preferred choice in modern plumbing systems, primarily due to their durability and longevity when compared to alternative valve types. According to a report by the American Society of Plumbing Engineers (ASPE), ball valves can last significantly longer than gate or globe valves, with a lifespan exceeding 20 years under optimal conditions. This extensive durability is largely attributed to their simple design, which minimizes wear and tear, ultimately leading to lower maintenance costs.

When considering the materials used for ball valves, many manufacturers opt for robust options like stainless steel or high-quality plastics, contributing to their ability to withstand high-pressure environments and corrosive substances. For instance, a study published in the Journal of Water Management suggests that stainless steel ball valves exhibit an impressive resistance to rust and corrosion, outperforming other materials in applications involving water and chemical transport.

**Tip:** When selecting ball valves for your plumbing system, look for models with a full-port design. This allows for minimal flow restriction and can enhance the overall efficiency of your plumbing. Additionally, always check the pressure ratings and compatibility with the fluids being transported to ensure longevity and optimum performance.

Understanding the Key Benefits of Using Ball Valves in Modern Plumbing Systems

| Feature | Ball Valves | Gate Valves | Globe Valves |

|---|---|---|---|

| Durability | High resistance to wear and tear | Moderate durability; susceptible to corrosion | Lower durability; prone to leakage over time |

| Operational Life | Long lifespan (up to 20 years or more) | Typically lasts 10-15 years | Generally lasts 5-10 years |

| Flow Efficiency | Minimal pressure drop; full-flow design | Moderate flow efficiency | Higher pressure drop; not ideal for high flow |

| Ease of Operation | Simple quarter-turn operation | Requires multiple turns to fully open or close | Requires more effort to operate |

| Maintenance | Low maintenance required | Regular maintenance needed to prevent seizure | Higher maintenance; regularly checked for leaks |

Ease of Operation: The User-Friendly Nature of Ball Valves

Ball valves are increasingly favored in modern plumbing systems due to their user-friendly nature, which greatly enhances ease of operation. Unlike other valve types, ball valves feature a simple quarter-turn operation, allowing for quick and effortless opening and closing. This design minimizes the risk of leaks, as the solid ball mechanism creates a tight seal with minimal effort. Homeowners and professionals alike benefit from this simplicity, especially during urgent repairs or routine maintenance.

Ball valves are increasingly favored in modern plumbing systems due to their user-friendly nature, which greatly enhances ease of operation. Unlike other valve types, ball valves feature a simple quarter-turn operation, allowing for quick and effortless opening and closing. This design minimizes the risk of leaks, as the solid ball mechanism creates a tight seal with minimal effort. Homeowners and professionals alike benefit from this simplicity, especially during urgent repairs or routine maintenance.

Moreover, the durability of ball valves contributes to their ease of use. They are constructed from robust materials that can withstand high pressure and temperature variations, making them ideal for various applications in plumbing systems. The maintenance required is minimal, allowing users to focus on other critical aspects of their plumbing instead of worrying about frequent replacements or repairs. Consequently, the reliable functionality of ball valves not only streamlines plumbing operations but also promotes a hassle-free experience for users, ensuring that they can manage their plumbing needs with confidence and efficiency.

Cost-Effectiveness: How Ball Valves Save Money in Plumbing Systems

Ball valves play a crucial role in modern plumbing systems, particularly when it comes to cost-effectiveness. As the residential construction landscape continues to expand in North America, the demand for ball valves is set to increase significantly, with forecasts projecting notable sales growth through 2035. This is largely driven by the heightened need for reliable and durable fixtures that contribute to efficient water management in homes. The simplicity of ball valves not only reduces maintenance costs but also minimizes the risk of leaks, which can lead to expensive water damage and higher utility bills.

In addition, the integration of advanced leak detection technology is elevating the functionality of plumbing systems. With insurance companies emphasizing proactive measures for water loss prevention, homeowners are more likely to invest in seamless solutions that include ball valves. The optimization of plumbing systems, enhanced by the strategic use of ball valves, supports better water conservation practices, which can lead to significant long-term savings. Efficient plumbing setups equipped with quality valves also promote compliance with local codes and standards, making them invaluable for both new constructions and retrofitting projects.

Related Posts

-

Exploring the Future of Stainless Ball Valves at the 138th China Import and Export Fair 2025

-

Understanding the Importance of Safety Valves in Preventing Industrial Accidents and Ensuring Compliance

-

Understanding the Benefits of Choosing Stainless Ball Valves for Your Plumbing Needs

-

The Essential Role of Cryogenic Valves in Modern Cryogenic Systems and Their Impact on Energy Efficiency

-

Innovative Trends in Low Pressure Relief Valves at the 2025 China Import and Export Fair

-

Unlocking Opportunities for Vacuum Check Valves at the 138th Canton Fair 2025 in China