2026 How to Choose the Right Control Valve for Your Application?

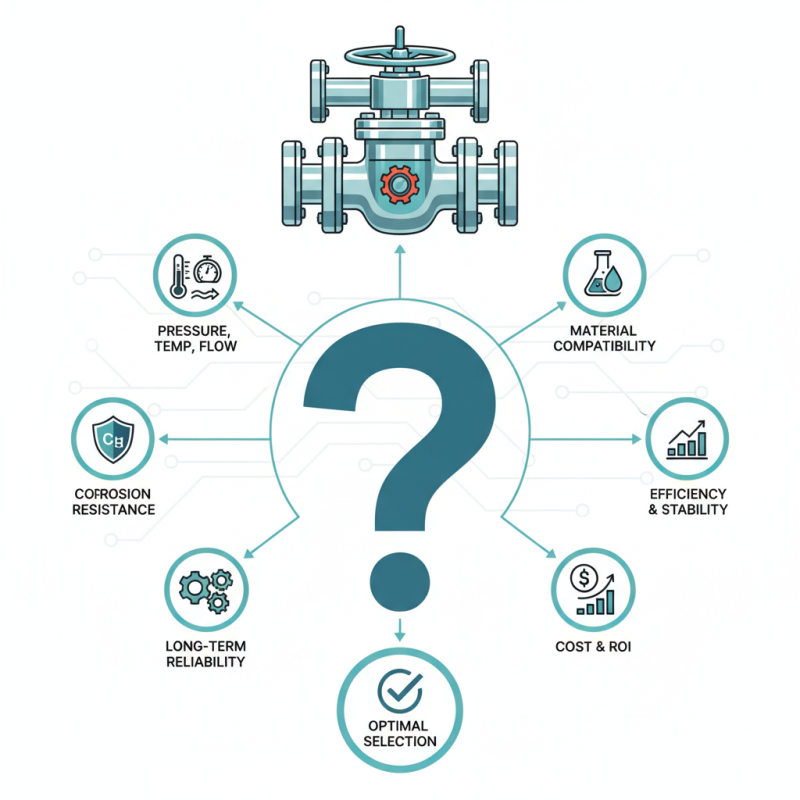

Choosing the right control valve for your application can be a complex task. Control valves play a crucial role in regulating fluid flow. They impact efficiency and process stability significantly. Each application has unique requirements. Understanding these needs is essential for optimal valve selection.

Consider factors like pressure, temperature, and flow rate. The wrong control valve can lead to inefficiencies and costly downtime. Some may overlook these details, leading to poor performance. Reflecting on past choices can help in making better decisions now.

Furthermore, the materials of the control valve must fit the media being controlled. Corrosion resistance, for example, is vital in certain applications. Evaluate the long-term implications of your selection. A well-chosen control valve can enhance system performance and longevity. The journey to find the right valve is often challenging, yet rewarding.

Understanding Control Valves: Types and Their Applications

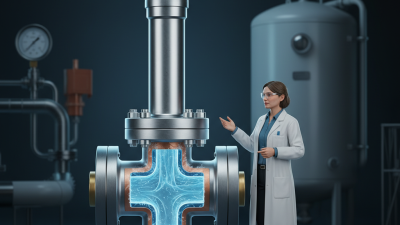

Control valves play a crucial role in various industrial applications. They regulate the flow of fluids and gases, ensuring systems operate efficiently. A shared understanding of the types of control valves is essential for making the right choice.

There are several types of control valves, including globe, gate, ball, and butterfly valves. Globe valves are ideal for throttling services. They offer great flow control. Ball valves, on the other hand, provide quick shut-off and are well-suited for isolating services. Butterfly valves are lightweight and simple. They are effective for large pipe diameters but may not provide the precise control needed in some applications.

Selecting the right valve is often a challenge. Factors like fluid type, pressure, and temperature must be considered. It’s easy to overlook the nuances of each valve type. One might assume a ball valve works well in every situation, but that’s not always true. The application's specific requirements should guide your choice. Sometimes, trial and error can lead to better decisions. Understanding the application will ultimately lead to improved efficiency and reduced costs.

Understanding Control Valves: Types and Their Applications

Key Factors in Selecting Control Valves for Specific Processes

Choosing the right control valve for a specific process can seem daunting. There are various factors to consider, such as flow characteristics, pressure drops, and media type. Each element has significant implications for performance. Understanding how each factor affects valve selection is crucial.

Flow characteristics play a vital role. Different processes require different flow rates. Often, achieving the desired flow may require compromises. Not all valves perform well at varying flow conditions. Evaluating the media is equally important. Corrosive substances need specialized materials. This might complicate the selection process.

Pressure drop should also be assessed carefully. Sometimes, a valve may appear suitable on paper but fails in practice. Often, users realize the importance too late. A detailed analysis of the operating environment can prevent such oversights. Each application is unique. Adjusting standards based on real-world conditions is necessary for optimal performance.

Evaluating Flow Characteristics and Sizing Control Valves

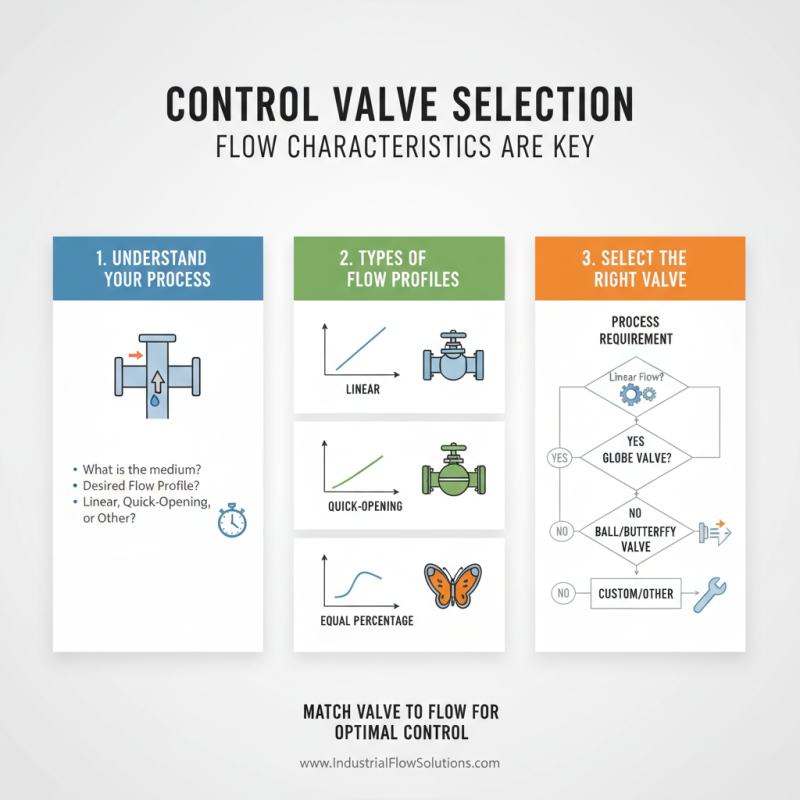

Choosing the right control valve starts with understanding flow characteristics. Different applications demand unique flow profiles. For instance, linear flow may suit some processes, while others require quick opening or closing responses. Knowing your process flow helps in selecting the correct valve.

Sizing control valves accurately is crucial. It impacts efficiency and performance. Oversized valves can lead to unstable flow and increased wear. Conversely, undersized valves may not handle the required flow rates. Each application comes with its own challenges. It is vital to calculate the correct Cv values based on your system's conditions.

Flow media needs consideration too. Liquids and gases behave differently under varying pressures and temperatures. For example, a gas may expand, affecting flow characteristics. Adjusting for these factors can be complex. Validating your choices through testing is always a wise step. Real-world conditions often differ from theoretical calculations. It’s essential to revisit and refine your selection as needed.

Material Selection for Control Valves in Harsh Environments

When selecting control valves for harsh environments, material choice is crucial. Common materials include

stainless steel, brass, and plastic.

Corrosion resistance is essential in chemical processes. For example, in

acidic environments, a material that withstands harsh chemicals is necessary.

However, many overlook the temperature sensitivity of these materials.

Thermal expansion can impact valve performance. Some metal valves might become brittle in

extreme conditions. On the other hand, plastic may deform under high temperatures.

It's important to consider both mechanical properties and environmental factors when making a choice.

Researching each material’s limits can save future headaches.

In some cases, the ideal material isn't straightforward. There might be trade-offs between

durability and flexibility. For example, while rubber offers flexibility,

it may not hold up against strong chemicals. Decision-makers must weigh these factors carefully. Often, the

decision involves trial and error to find the right balance.

Consider consulting experts when necessary. They can provide insights that lead to better material selection.

Cost vs. Performance: Making Informed Decisions in Valve Selection

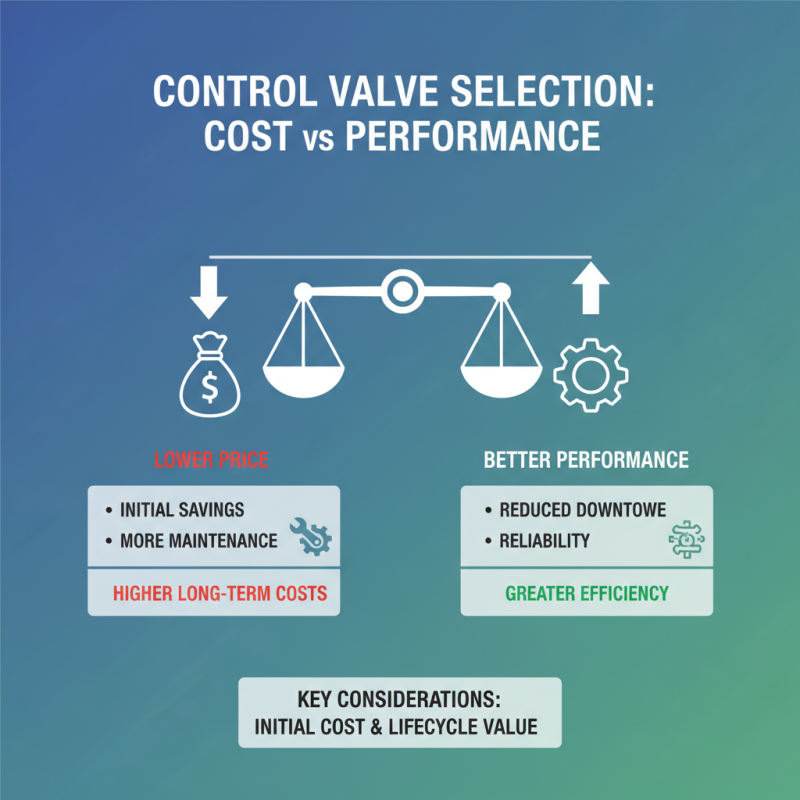

Choosing the right control valve can be challenging. Factors like cost and performance must be considered carefully. A lower-priced valve may save money upfront, but could lead to more maintenance issues later. The initial savings might not justify the long-term expenses.

Performance is crucial. A valve that frequently malfunctions can disrupt operations. This can result in costly downtimes. Think about how often the valve will be used and the conditions it faces. A robust design often pays off. Don't overlook the importance of materials and construction. They can impact longevity and effectiveness.

Consider long-term needs. Are you planning to expand or change processes? This could require a different type of valve. Sometimes, the cheapest option leads to ongoing repairs, which adds up. Balancing cost with performance ensures you make a sound decision. Reflect on your priorities, and choose wisely.

Related Posts

-

10 Best Control Valves for Optimal Process Management?

-

Understanding the Importance of Control Valves in Modern Industrial Applications

-

Understanding the Importance of Relief Valves in Modern Industrial Applications

-

The Essential Role of Cryogenic Valves in Modern Cryogenic Systems and Their Impact on Energy Efficiency

-

Why a Safety Valve is Essential for Industrial Equipment in 2026

-

What is a Cryogenic Valve and How Does it Work?