10 Essential Tips for Choosing the Right High Pressure Valve

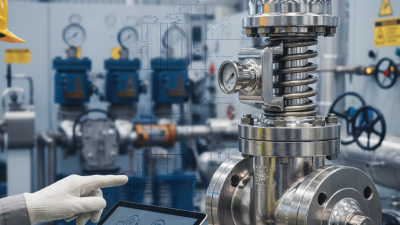

Choosing the right high pressure valve is crucial for any industrial application. Industry expert John Smith emphasizes, "Selecting the right valve can greatly impact safety and efficiency." Valves play a vital role in controlling fluid flow under high pressure. A wrong choice can lead to costly issues or even hazardous situations.

Many factors influence this decision. First, consider the valve materials. They must withstand the pressure and the fluid's chemical properties. Additionally, valve size and type matter. Each application might require a different configuration. Seeking advice from experienced professionals is often necessary. However, one must think critically about these choices.

It's easy to overlook the importance of maintenance. Even the best high pressure valve will fail without proper care. Buyers should reflect on past experiences. Often, mistakes arise from ignoring the specifics. Taking time to assess all aspects can lead to a better outcome. In the end, informed decisions in high pressure valve selection promote safety and performance.

Understanding High Pressure Valves and Their Applications

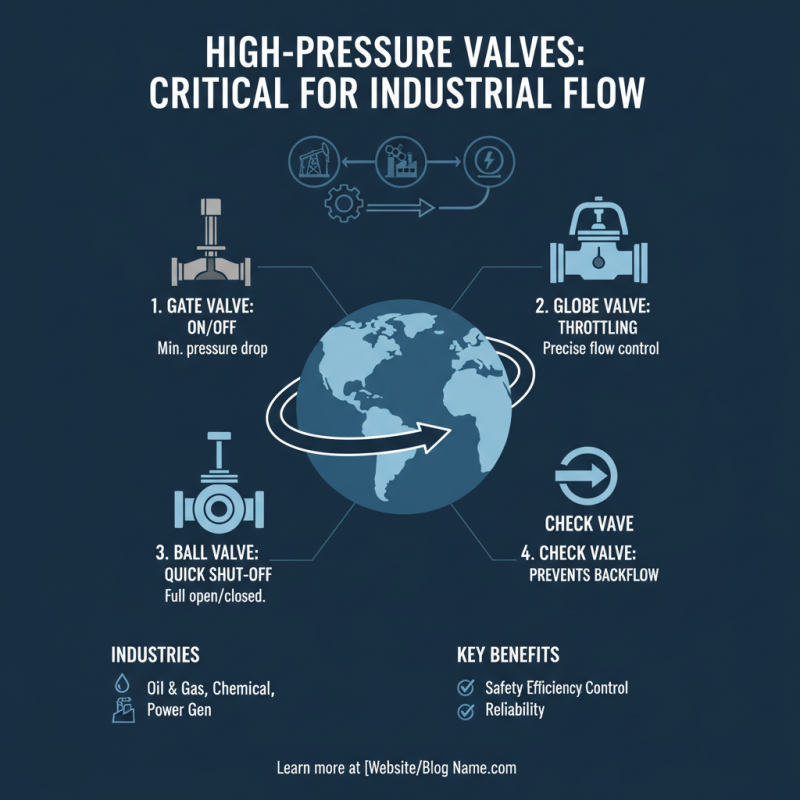

High pressure valves play a crucial role in various industries such as oil, gas, and water treatment. They control the flow of fluids under high pressure, making them essential for safety and efficiency. Understanding the types of high pressure valves is vital. You have gate valves, globe valves, check valves, and ball valves. Each type has unique functions and applications, from regulating flow to preventing backflow.

Choosing the right valve can be challenging. Consider the specific application and required pressure levels. Is it for a high-temperature environment? Will it handle corrosive substances? These questions are crucial for making an informed decision. Sometimes, even experienced engineers overlook specifications. A mismatched valve can lead to leaks or system failures. Small errors in choice can have significant consequences.

In the long run, it's not just about performance. Reliability and longevity of the valve matter too. Frequent replacements can be costly and disruptive. So, reflect on your choices and gather insights from industry professionals. A well-chosen valve can enhance system efficiency and reduce maintenance needs. Don't rush this decision; take time to analyze all factors involved.

High Pressure Valve Application Overview

This chart illustrates the distribution of various applications for high pressure valves across different industries. The data represents the percentage of applications in sectors such as oil and gas, water treatment, chemical processing, and power generation.

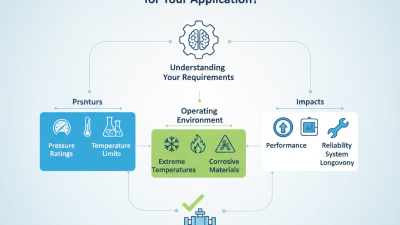

Key Factors to Consider When Selecting a High Pressure Valve

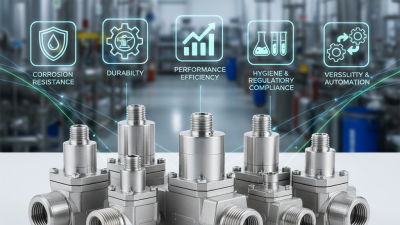

When selecting high pressure valves, certain key factors must be considered to ensure optimal performance. The pressure rating is crucial. Typically, valves should meet or exceed the system’s maximum pressure. According to a 2022 report from the Fluid Control Industry Association, nearly 30% of valve failures arise from inadequate pressure ratings. Users should also consider the valve’s material. Common materials like stainless steel or brass offer different strengths and corrosion resistances. A mismatch can lead to premature wear and costly repairs.

Temperature limits also play a role. High pressure valves may face extreme temperatures. An analysis from the Engineering Valves Journal indicates that heat can severely impact valve integrity. Understanding the operating environment is vital. Choose valves with a proven track record under similar conditions. If uncertain, seek expert opinions. It’s essential to reflect upon past selections. An incorrect choice can lead to operational failures or safety hazards. Always double-check specifications to avoid these pitfalls. Ensure that your selection aligns with industry standards for maximum reliability.

10 Essential Tips for Choosing the Right High Pressure Valve - Key Factors to Consider When Selecting a High Pressure Valve

| Factor | Description | Importance |

|---|---|---|

| Pressure Rating | Determine the maximum pressure the valve will be subjected to in service. | High |

| Material Compatibility | Ensure the valve material can withstand the media being handled. | Critical |

| End Connections | Select the appropriate connection type (e.g., threaded, flanged) for installation. | Moderate |

| Flow Characteristics | Understand how the valve will affect flow rate and pressure drop. | High |

| Temperature Range | Check the operating temperature range for the valve and the media. | High |

| Actuation Type | Decide whether manual, pneumatic, or electric actuation is needed. | Moderate |

| Compliance Standards | Verify that the valve meets necessary industry standards and regulations. | Critical |

| Size and Dimensions | Choose the right size to fit into your system without any issues. | High |

| Maintenance Requirements | Consider how often the valve will need maintenance and ease of access. | Moderate |

| Cost | Balance between initial investment and lifecycle costs of the valve. | High |

Different Types of High Pressure Valves and Their Functions

High pressure valves are essential in various industries, including oil and gas, chemical processing, and power generation. They control fluid flow, ensuring safety and efficiency. Understanding different types of valves is crucial for choosing the right one.

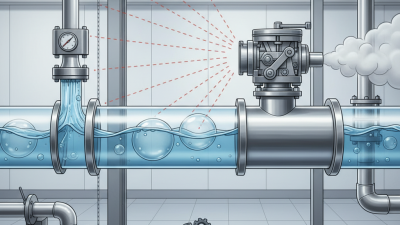

Gate valves are commonly used for on/off control with minimal flow restriction. They are effective but can be slow to operate. Globe valves, in contrast, allow for more precise flow regulation. However, they can create pressure drops. A report by the American Society of Mechanical Engineers (ASME) shows that more than 60% of industrial leaks come from improperly maintained valves.

Ball valves offer quick shutoff capabilities and are durable. They are suitable for applications needing tight sealing. Butterfly valves can also be used for adjustable flow control, but they may suffer from wear over time. A recent study indicates that selecting the appropriate valve can reduce maintenance costs by 20% and enhance operational safety. It’s vital to weigh these differences carefully. Overlooking the specific requirements of your application could lead to serious operational challenges.

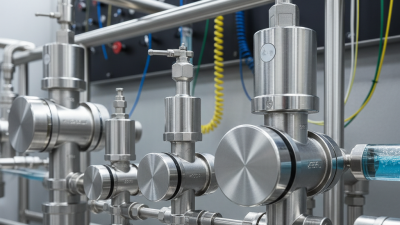

Material Selection for High Pressure Valves: What You Need to Know

When selecting high pressure valves, material choice is crucial. The wrong material can lead to failures. Common materials include stainless steel, brass, and titanium. Each has its advantages and drawbacks. For example, stainless steel is corrosion-resistant but can be expensive. Brass is versatile and affordable but less durable.

Temperature and pressure ratings also affect material selection. High temperatures can weaken some metals. In extreme conditions, synthetic materials might perform better. It's important to consider the specific application. Valve exposure to chemicals adds another layer of complexity. Not all materials resist all substances.

Testing the selected materials is essential. Even with the best choices, unexpected issues can arise. Regular inspections can prevent costly breakdowns. Be prepared to adjust your choices based on real-world performance. Sometimes, a lower-cost option could work just as well. Always keep safety in mind while making decisions. Balancing cost, durability, and application requirements is challenging but necessary.

Importance of Sizing and Pressure Ratings in High Pressure Valves

When selecting high pressure valves, understanding sizing and pressure ratings is crucial. An incorrectly sized valve can lead to inefficiency. Valves must match the system's requirements.

Too small a valve may restrict flow. Conversely, a valve that is too large can cause pressure drops.

Pay attention to the pressure rating. This rating indicates the maximum pressure the valve can handle. If the rating is too low, it can fail under pressure. Look for details about the material. Different materials can withstand varying pressure levels. Always consult technical specifications.

Tip: Measure your pipeline accurately before purchasing. This ensures the valve fits well. It’s also wise to consider future changes in pressure needs. Staying informed helps avoid costly mistakes.

Another tip is to test the valve at different pressure levels. This can reveal hidden weaknesses. Sometimes, an underestimated valve can lead to safety risks. Reflect on your choices. The wrong valve can be a significant issue in high pressure systems.

Related Posts

-

Top Tips for Choosing and Maintaining Stainless Steel Solenoid Valves

-

Top 5 Benefits of Using Stainless Steel Solenoid Valves in Industry

-

How to Choose the Right Safety Valve for Your Application?

-

Ultimate Guide to Valve Tags in 2025 Trends and Best Practices

-

2026 How to Choose the Right Solenoid Valve for Your Application?

-

Why Do You Need an Air Valve in Your System?