The Essential Role of Cryogenic Valves in Modern Cryogenic Systems and Their Impact on Energy Efficiency

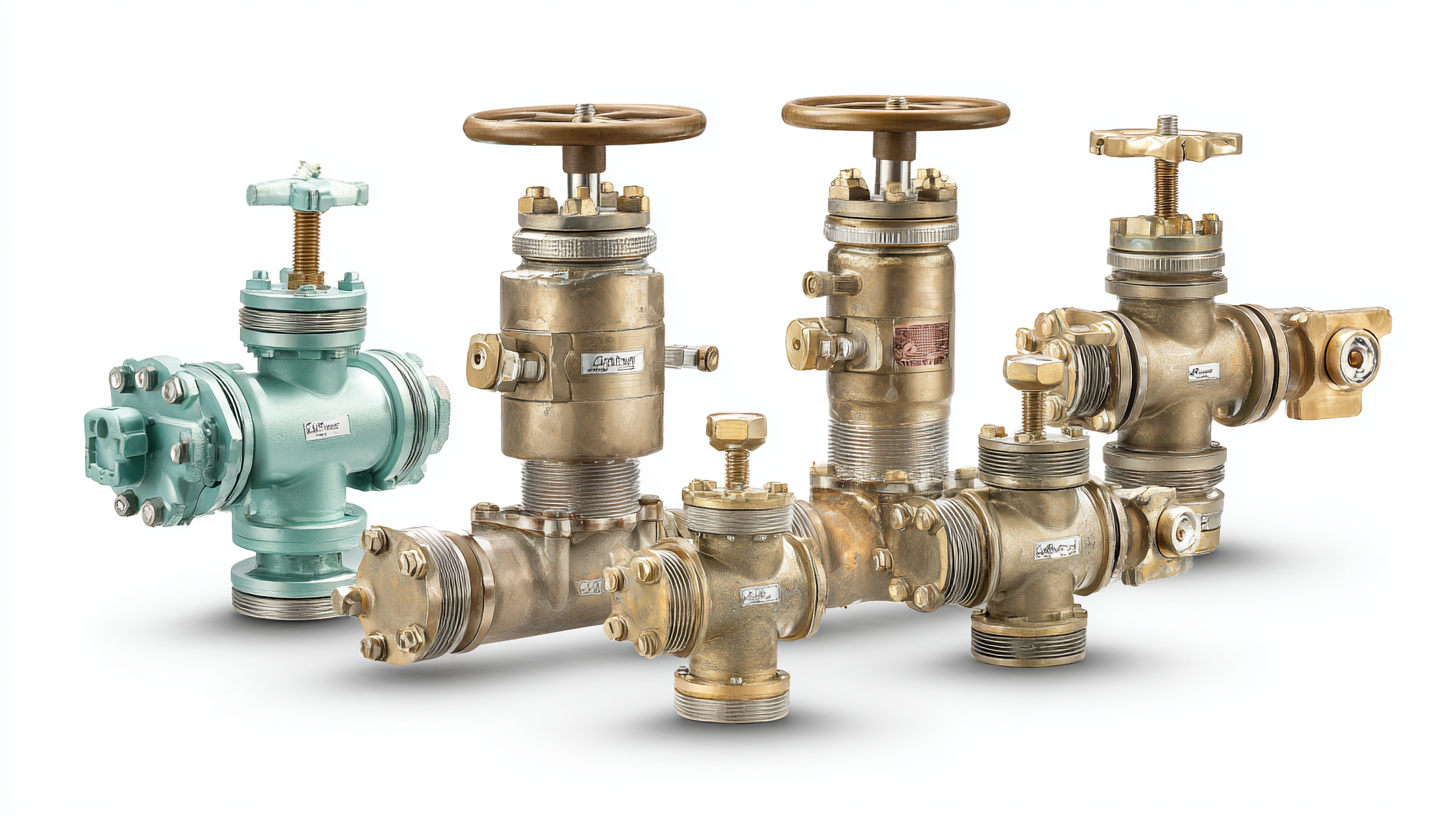

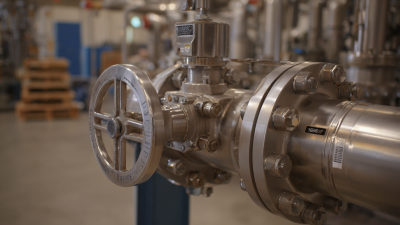

In the realm of modern cryogenic systems, cryogenic valves play an essential role in ensuring effective operation and enhanced energy efficiency. These specialized valves are critical for controlling and directing the flow of cryogenic fluids at extremely low temperatures, which are indispensable in various industries, from aerospace to liquefied natural gas (LNG) applications.

Understanding how to choose, install, and maintain cryogenic valves can significantly impact the performance of these systems, leading to reduced energy consumption and improved safety. As the demand for energy-efficient solutions grows, mastering the intricacies of cryogenic valves becomes increasingly important for engineers and technicians alike. This guide aims to provide insights into the fundamental aspects of cryogenic valves, their operational principles, and best practices for optimizing cryogenic system efficiency.

The Importance of Cryogenic Valves in Today's Energy Systems

Cryogenic valves play a crucial role in the efficiency and functionality of today's energy systems, particularly as the demand for sustainable and energy-efficient technologies continues to rise. These specialized valves are essential for managing the flow of cryogenic fluids, which are vital in applications such as liquefied natural gas (LNG) production, space exploration, and various industrial processes. Their ability to withstand extreme temperatures allows for proper control and containment of supercooled gases, which optimizes energy transfer and reduces waste.

Cryogenic valves play a crucial role in the efficiency and functionality of today's energy systems, particularly as the demand for sustainable and energy-efficient technologies continues to rise. These specialized valves are essential for managing the flow of cryogenic fluids, which are vital in applications such as liquefied natural gas (LNG) production, space exploration, and various industrial processes. Their ability to withstand extreme temperatures allows for proper control and containment of supercooled gases, which optimizes energy transfer and reduces waste.

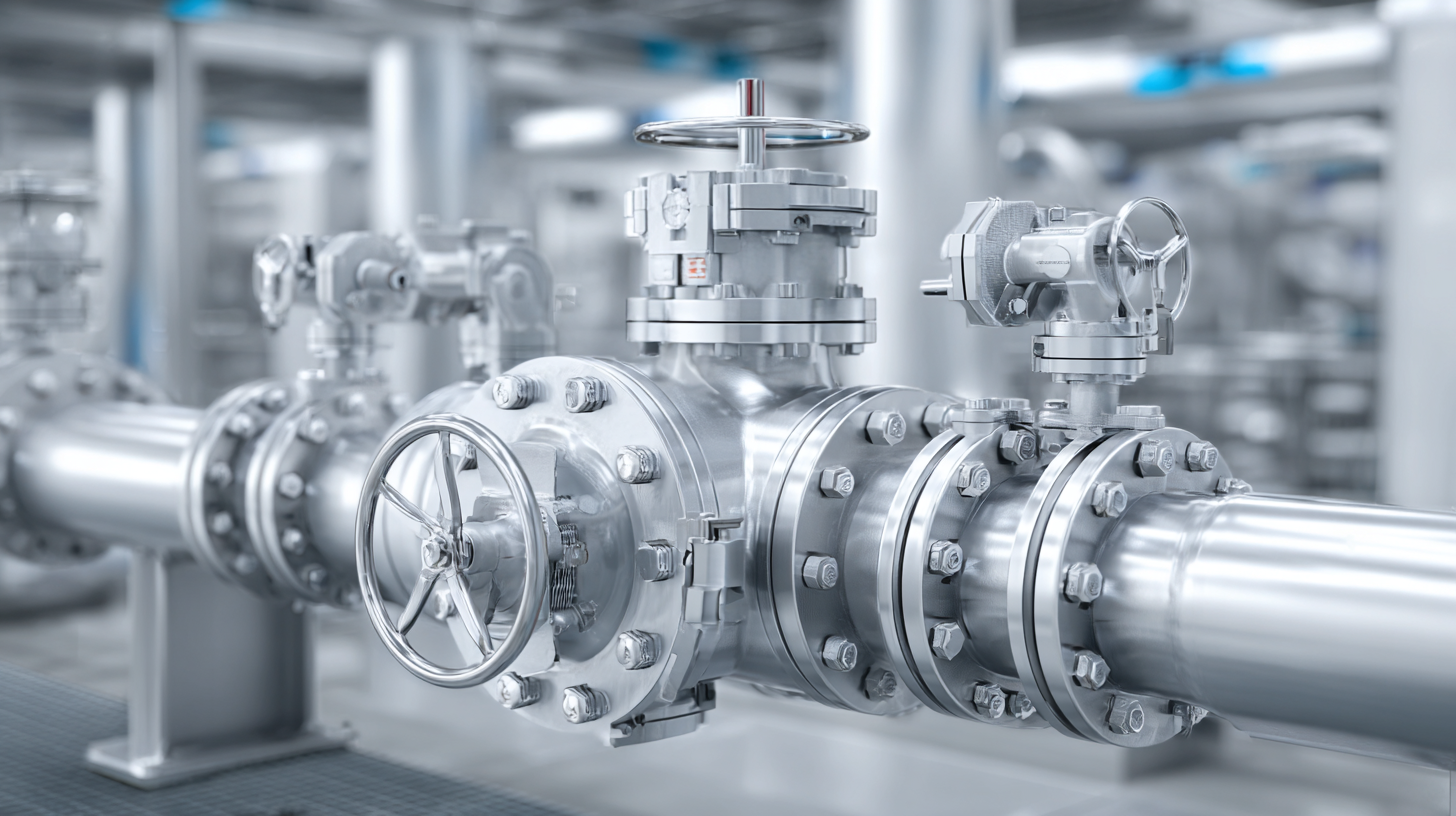

In modern energy systems, the efficiency of cryogenic valves directly impacts overall system performance. By facilitating precise control of fluid dynamics in cryogenic environments, these valves minimize energy loss during transportation and storage. Moreover, advancements in valve design and materials contribute to enhanced reliability and reduced maintenance costs, further supporting energy conservation efforts. As industries increasingly adopt cryogenics to achieve sustainability goals, the importance of high-performance cryogenic valves cannot be overstated, making them a critical component in the quest for improved energy efficiency.

Key Features of Cryogenic Valves Enhancing System Performance

Cryogenic valves are indispensable components in modern cryogenic systems, specifically designed to operate in extremely low-temperature environments. Their key features significantly enhance overall system performance, primarily by ensuring precise control over the flow of cryogenic fluids. For instance, the ability of these valves to maintain tight sealing under cryogenic conditions prevents fluid loss, thereby increasing energy efficiency. According to a report by the Cryogenic Engineering Conference, properly selected and maintained cryogenic valves can lead to a reduction in energy consumption by up to 20%, underscoring their critical role in optimizing system performance.

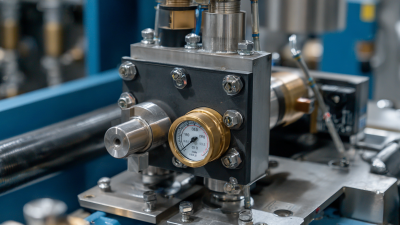

Moreover, advanced materials and innovative designs in cryogenic valves contribute to improved reliability and longevity. High-quality stainless steel and special alloys are commonly used to withstand the stresses of low temperatures while minimizing thermal contraction effects. Data from the International Cryogenics Association indicate that robust valve designs can enhance operational lifespan by approximately 30%, reducing maintenance costs and downtime. Features such as automated actuators and smart monitoring systems further ensure that valves perform efficiently and reliably, maximizing energy savings across various applications, including liquefied natural gas and superconducting technology.

The Essential Role of Cryogenic Valves in Modern Cryogenic Systems

The chart above illustrates the performance metrics of key features in cryogenic valves which enhance the overall efficiency and effectiveness of modern cryogenic systems. Each metric represents the capabilities of cryogenic valves in crucial areas that influence energy efficiency and operational reliability.

How Cryogenic Valves Contribute to Overall Energy Efficiency

Cryogenic valves play a pivotal role in enhancing energy efficiency within modern cryogenic systems. These specialized components are designed to regulate the flow and pressure of cryogenic fluids, which are essential in a multitude of applications, from liquefied natural gas (LNG) processes to aerospace technologies. By maintaining optimal operating conditions, cryogenic valves significantly reduce energy losses caused by improper flow regulation, resulting in a more efficient cooling cycle.

Additionally, the precision engineering of cryogenic valves ensures minimal leakage and maximized control over thermal management. This not only preserves the integrity of the cryogenic fluids but also contributes to lower operational costs. When cryogenic systems operate efficiently, they consume less energy, thereby aligning with global sustainability goals. The integration of advanced cryogenic valve technology supports innovations in energy-efficient designs, ultimately helping industries to reduce their carbon footprint while enhancing the overall reliability and performance of their cryogenic systems.

Innovations in Cryogenic Valve Technology and Their Benefits

Innovations in cryogenic valve technology have significantly enhanced the efficiency and reliability of modern cryogenic systems. According to a report by MarketsandMarkets, the global cryogenic valve market is expected to reach $4.2 billion by 2025, growing at a CAGR of 5.2%. This growth reflects the increasing demand for advanced cryogenic applications across various industries, including aerospace, natural gas, and medical.

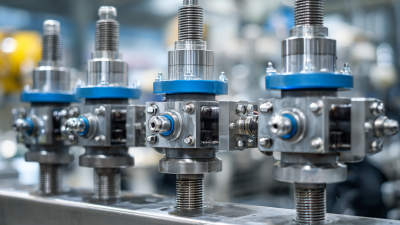

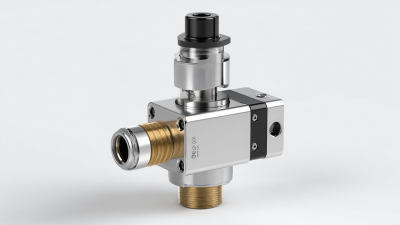

One notable advancement is the development of smart cryogenic valves equipped with IoT capabilities. These valves allow for real-time monitoring and remote control, which not only improves operational efficiency but also reduces downtime. For instance, a recent study published in the Journal of Cryogenic Systems highlighted that the integration of smart valves can lead to a reduction in energy consumption by up to 20%, significantly impacting the overall sustainability of cryogenic processes. The ability to ensure precise control over cryogenic fluids further enhances system performance, making these innovations crucial in achieving higher energy efficiency in modern applications.

Additionally, the use of advanced materials such as Inconel and specialized polymers has led to improved durability and performance in extreme temperatures. These materials enable valves to withstand cryogenic environments without compromising safety or efficiency. According to the Cryogenic Society of America, the adoption of high-performance cryogenic valve technologies can enhance energy efficiency by up to 30%, contributing to significant cost savings for industries reliant on cryogenic systems.

Future Trends in Cryogenic Systems and Valve Developments

The future of cryogenic systems is poised for significant advancements, particularly in the realm of valve technologies. As industries increasingly prioritize energy efficiency and sustainability, innovations in cryogenic valves are becoming essential. Advancements such as smart sensors and automation are expected to enhance the performance of these valves, enabling real-time monitoring and adjustments that optimize system efficiency. This integration will not only reduce energy consumption but also lead to more reliable operations in applications like liquefied natural gas (LNG) transport and storage.

Furthermore, the development of advanced materials will play a crucial role in the evolution of cryogenic valves. New alloys and composites are being researched to improve the durability and thermal efficiency of valves at extremely low temperatures. These materials can minimize thermal losses and ensure better sealing capabilities, significantly impacting overall system effectiveness. As cryogenic technologies continue to evolve, the collaboration between manufacturers and end-users will be vital in driving innovations that meet the growing demands for energy-efficient solutions across various sectors.

The Essential Role of Cryogenic Valves in Modern Cryogenic Systems and Their Impact on Energy Efficiency - Future Trends in Cryogenic Systems and Valve Developments

| Dimension | Description | Value |

|---|---|---|

| Operating Temperature Range | Typical range for cryogenic valves | -196°C to -40°C |

| Pressure Rating | Maximum allowable pressure for safe operation | 150 bar |

| Materials Used | Common materials for cryogenic valve construction | Stainless Steel, Brass, Inconel |

| Flow Coefficient (Cv) | Measure of the valve's ability to allow fluid flow | 1.5 to 10 |

| Energy Efficiency Improvement | Potential energy savings through modern valve technology | Up to 20% |

| Future Trends | Emerging technologies and developments in cryogenic valves | Smart Valves, IoT Integration, Lightweight Materials |

Related Posts

-

Unlocking the Efficiency of Cryogenic Solenoid Valves: A Deep Dive into Their Applications and Performance Data

-

Essential Guide to Understanding High Pressure Relief Valves: How They Ensure Safety in Industrial Applications

-

Exploring the Future of Stainless Ball Valves at the 138th China Import and Export Fair 2025

-

Innovative Trends in Low Pressure Relief Valves at the 2025 China Import and Export Fair

-

The Ultimate Guide to Choosing the Right Flow Check Valve for Your System Needs

-

Unlocking Opportunities for Vacuum Check Valves at the 138th Canton Fair 2025 in China