How to Choose the Right Safety Valve for Your Application?

Choosing the right safety valve is crucial for ensuring equipment safety and operational efficiency. According to the latest industry report by the Valve Manufacturers Association, improper valve selection leads to a significant percentage of system failures. Data shows that nearly 30% of companies faced operational disruptions due to safety valve issues last year. This highlights the importance of thoughtful selection.

Expert Jane Patterson, a renowned safety valve consultant, emphasizes, "A safety valve should match your application requirements precisely." Her insight underscores a common pitfall: selecting valves without understanding specific needs. Each application has unique pressure and temperature demands that affect performance.

Moreover, many engineers overlook maintenance recommendations from manufacturers. Regular checks are essential for reliability. Choosing a safety valve is not just about compliance; it's about safeguarding lives and investments. In a world where safety cannot be compromised, understanding the nuances of valve selection is pivotal.

Understanding the Basics of Safety Valves and Their Functions

Safety valves are critical components in various industrial applications. They prevent overpressure conditions, protecting both equipment and personnel. According to a report by the International Society of Automation, improper valve sizing can lead to 30% of equipment failures. Understanding the basic functions of safety valves is essential before any application.

Safety valves work by automatically releasing pressure when it exceeds predetermined limits. This helps to prevent catastrophic failures. The American Society of Mechanical Engineers emphasizes that a well-functioning safety valve can save millions in potential damages. Incorrect installation and maintenance, however, pose significant risks. Many facilities overlook routine checks, leading to malfunctioning valves in critical situations.

When selecting a safety valve, consider application specifics. Factors like pressure, flow rate, and fluid type are vital. For example, steam applications require different materials than corrosive chemicals. A miscalculation can result in severe consequences. Experience indicates that many operators underestimate these factors, which can lead to operational inefficiencies and safety hazards. Recognizing the nuances of safety valve implementation is crucial for a reliable system.

How to Choose the Right Safety Valve for Your Application?

| Criteria | Description | Common Applications | Material |

|---|---|---|---|

| Pressure Rating | The maximum pressure the valve can handle. | Boilers, Pressure vessels | Stainless Steel |

| Flow Capacity | The amount of fluid the valve can release. | Hydraulic Systems, Gas Pipelines | Brass |

| Valve Type | Different designs such as spring-loaded or pilot-operated. | Chemical Processing, Oil and Gas | Carbon Steel |

| Temperature Range | The temperature limits for safe operation. | Power Generation, Heating Systems | Alloy Steel |

| Sealing Mechanism | The method of sealing to prevent leaks. | Water Treatment, Food Processing | PTFE, Rubber |

Identifying Your Application Requirements for Safety Valve Selection

Choosing the right safety valve requires a clear understanding of your application needs. Begin by evaluating the maximum pressure and temperature of your system. Consider the type of medium, whether gas, liquid, or vapor. Additionally, know the flow rate you expect to prevent issues down the line.

Think about the environment where the valve will operate. Harsh conditions, like extreme temperatures or corrosive agents, can affect valve performance. Make sure to assess any space constraints too. A compact design could be necessary for tight installations.

You may face difficulties balancing all these factors. Each application has unique challenges. Sometimes, you might feel overwhelmed by choices. Reflect on past experiences and what went wrong. Consulting with experts can clarify doubts, but remember, no one solution fits all. Explore various options thoroughly to enhance your selection process.

Key Factors to Consider When Choosing a Safety Valve

Selecting the right safety valve is crucial for any application. The first factor to consider is the pressure rating. It must match your system’s requirements. A valve selected with insufficient pressure could fail.

Another key aspect is the material. Different materials withstand different conditions. For example, corrosive environments need specialized materials. Ensure the valve can handle your specific application.

**Tips:** Check compatibility with fluids. Understanding fluid characteristics aids selection. Test the valve regularly to ensure functionality. Regular maintenance prolongs lifespan.

Form factor also matters. Some applications require compact sizes. Ensure that the chosen valve fits the space available. A mismatch can lead to operational issues or installation troubles.

**Tips:** Measure carefully before purchasing. Sometimes, size constraints can lead to poor performance. Always prioritize safety over aesthetics.

Safety Valve Selection Criteria

This chart illustrates the key factors to consider when choosing a safety valve for your application, rated on a scale of 1 to 10 for their importance. Ensuring the correct size and pressure rating is vital, while material selection and spring type also contribute significantly to overall performance.

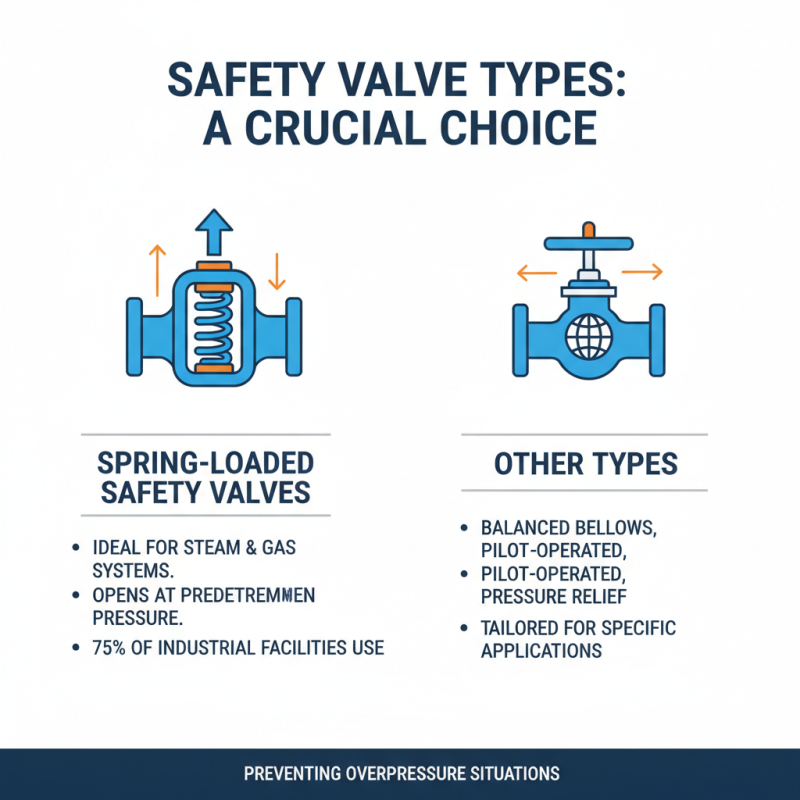

Types of Safety Valves and Their Specific Applications

When choosing safety valves, understanding the types available is crucial. There are several forms of safety valves, each tailored for specific applications. For instance, spring-loaded safety valves work well in steam and gas systems. These valves are designed to open at a predetermined pressure, allowing excess pressure to escape. Reports show that up to 75% of industrial facilities utilize these valves due to their reliability and efficiency in preventing overpressure situations.

Another type is pilot-operated safety valves. These are used in high-flow applications. They rely on an external pilot system to control opening and closing. Data indicates that nearly 60% of high-capacity systems prefer pilot-operated designs. However, their complexity can lead to maintenance challenges. Operators might overlook the necessity of routine checks.

Finally, there are balanced bellows safety valves, ideal for corrosive environments. These valves feature a design that minimizes the effect of backpressure on their performance. Statistics reveal that around 30% of chemical processing plants utilize these valves. Nevertheless, users should regularly assess their performance. Ignoring wear and tear could lead to potential failures. Understanding these types helps ensure that the right safety valve is selected for any application.

How to Ensure Compliance with Safety Valve Regulations and Standards

When selecting a safety valve, compliance with regulations is crucial. Industry standards ensure equipment operates safely and effectively. The American Society of Mechanical Engineers (ASME) outlines key requirements for safety valves. According to ASME's Boiler and Pressure Vessel Code, these valves must meet specific design and testing criteria. This guarantees their reliability in emergency situations.

Failure to adhere to these guidelines can lead to severe consequences. Reports highlight that non-compliant safety systems contribute to 20% of industrial accidents. Regular inspections and documentation are vital. Operators must ensure that all safety valves are certified and maintained. This helps in preventing operational failures.

Moreover, staying updated on local regulations is essential. Each region may have unique standards that differ from global ones. Engaging with industry professionals can provide insights into best practices. Many facilities struggle with maintaining compliance due to rapidly changing regulations. Regular training can bridge this gap and enhance safety awareness within teams.

Related Posts

-

Why a Safety Valve is Essential for Industrial Equipment in 2026

-

Understanding the Importance of Relief Valves in Modern Industrial Applications

-

Understanding the Essential Role of Pressure Vacuum Valves in Modern Industrial Systems

-

Understanding the Importance of Safety Valves in Preventing Industrial Accidents and Ensuring Compliance

-

What is a Pressure Control Valve and How Does It Work in Different Applications

-

Top 10 Pressure Control Valves: Features, Benefits, and Buying Guide