How to Choose the Right Electronic Valve for Your System?

In today's rapidly evolving industrial landscape, selecting the right electronic valve is crucial for efficient operations. According to a report by MarketsandMarkets, the electronic valve market is projected to reach $12 billion by 2025, driven by increased automation and smart manufacturing needs. However, many companies still face challenges in making the right choice.

Expert Mark Thompson, a leader in valve technology, emphasizes the importance of compatibility: "Choosing an electronic valve that fits seamlessly into your system is vital." His insight reflects a common struggle among industry professionals. Often, factors such as valve type, material, and control method are overlooked, leading to compatibility issues.

Real-life experiences show that improper valve selection can cause significant downtime. In some cases, businesses reported 30 days of lost productivity due to valve-related problems. As industries advance, the need for informed decisions on electronic valves becomes even more critical. Organizations must balance performance and cost while considering long-term sustainability. Making the right choice is not just about technology; it is about maintaining operational integrity.

Understanding Electronic Valves and Their Applications

Electronic valves are crucial components in various industries, offering precision control over fluid and gas flow. The versatility of electronic valves makes them suitable for applications in HVAC systems, automotive, and industrial processes. According to a recent industry report, the global electronic valve market is projected to reach $5.4 billion by 2025, growing at a CAGR of 10% from 2020. This indicates a rising demand for innovative solutions.

Understanding the specific applications of electronic valves can help optimize system performance. In HVAC systems, for instance, electronic valves regulate temperature and enhance energy efficiency. However, improper selection can lead to inefficiencies. A poorly matched valve may cause pressure drops or increase maintenance costs.

Data shows that about 30% of contractors report challenges in valve selection. Factors such as fluid type, pressure levels, and temperature ranges must be carefully considered. Neglecting these aspects can result in poor system performance. The choice of valve material and actuation method also plays a significant role. A deep understanding of these applications is vital for achieving reliable performance.

Key Factors to Consider When Selecting an Electronic Valve

Choosing the right electronic valve is crucial for system performance. Various industry reports indicate that over 35% of system failures are attributed to improper valve selection. This makes understanding key factors essential.

One significant factor is the operating pressure. Different applications require different pressure ratings. The American Society of Mechanical Engineers (ASME) suggests evaluating the maximum pressure the valve may experience. This prevents potential failures and enhances safety. Additionally, the medium being controlled plays a vital role. Specific materials and designs may react chemically with fluids or gases, leading to leaks or breakdowns.

Another essential aspect is the valve's response time. Fast response is critical in processes that rely on precise control. Research indicates that a delay of even a few seconds can impact system efficiency significantly. However, faster isn’t always better. An unfiltered high-speed valve can cause vibrations and noise, affecting the overall system. Consider both speed and stability for optimal operation.

How to Choose the Right Electronic Valve for Your System? - Key Factors to Consider When Selecting an Electronic Valve

| Factor | Consideration | Recommended Range |

|---|---|---|

| Pressure Rating | Maximum pressure the valve can withstand | 0 to 600 psi |

| Temperature Range | Operating temperature limits for optimal performance | -40°C to 150°C |

| Flow Rate | Volume of fluid that can pass through the valve | 0.5 to 5,000 L/min |

| Material Compatibility | Must be compatible with the fluids used | PVC, Brass, Stainless Steel |

| Operating Voltage | Required voltage for the valve's operation | 12V, 24V, 110V |

| Actuation Type | Mechanism used to operate the valve | Solenoid, Pneumatic, Electric Motor |

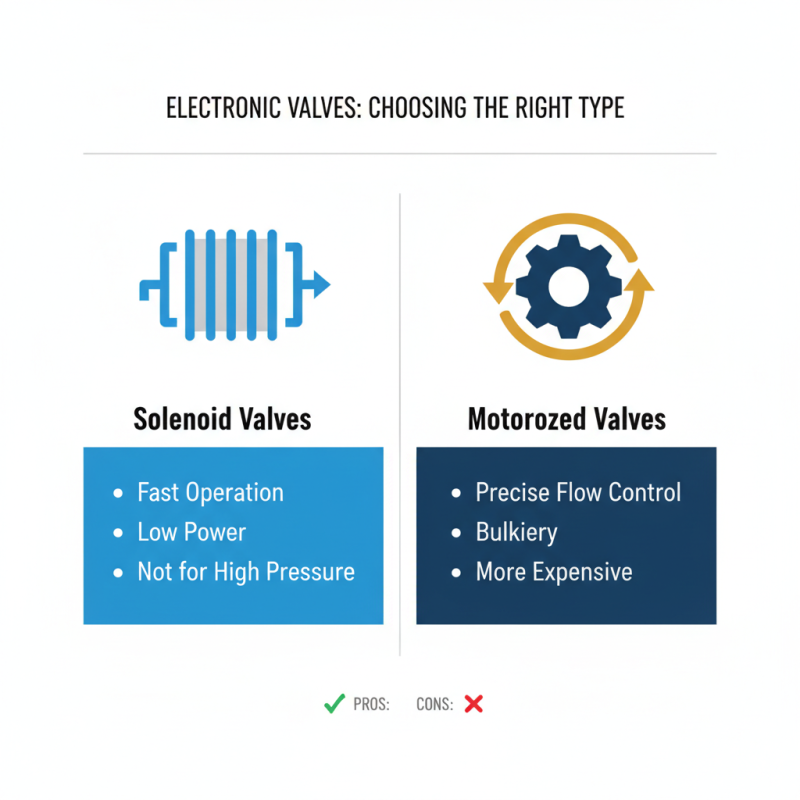

Types of Electronic Valves: Pros and Cons

When choosing an electronic valve, understanding the types available is crucial. Solenoid valves are a popular choice. They offer fast operation and low power consumption. However, they may struggle with high-pressure applications. Then there are motorized valves. These are great for precise flow control. Yet, they can be bulkier and more expensive.

Pneumatically actuated valves are another option. They respond quickly to changes, making them suitable for dynamic systems. On the flip side, they often require compressed air. This can complicate the installation process. Lastly, consider proportional valves. They allow for fine adjustments in flow rates. Unfortunately, they may not be as reliable under extreme conditions.

Each type has its own strengths and weaknesses. It’s essential to weigh these aspects carefully. Some decisions may lead to inefficiencies in your system. Reflecting on your requirements is key. What works in one scenario may fail in another. Ultimately, being thorough in your decisions can yield better results.

Evaluating Compatibility with Your System's Specifications

When evaluating compatibility, assess your system's specifications carefully. Understanding pressure, temperature, and flow rates is essential. According to industry reports, 30% of valve failures are due to compatibility issues. This emphasizes the need for thorough evaluation.

Materials matter too. A valve's material should withstand the chemicals in your system. For instance, corrosive substances can degrade certain metals. A failed valve can disrupt operations and incur significant costs. Ensure that the valve can handle these conditions.

Often, users overlook control methods. How will you operate the valve? Electric, pneumatic, and manual options exist. Each has distinct advantages. Research indicates that 40% of users experienced inefficiencies due to improper control method choice. Evaluate your system's needs to avoid costly mistakes.

Maintenance and Performance Considerations for Electronic Valves

When selecting electronic valves, consider their maintenance and performance carefully. Regular maintenance is crucial for optimal function. Check for leaks or unusual sounds. A simple inspection can reveal much. Dirt and debris can cause malfunctions. Clean valves frequently to prevent buildup. Sometimes, this can be overlooked, leading to bigger problems later.

Performance should also be monitored consistently. Ensure valves are responding to commands accurately. If they are slow to react, it may be time for calibration. Sometimes, feedback from operators is invaluable. They often notice issues before they become critical. Track the performance over time for insights. Regular performance reviews can enhance reliability. Decisions based on data are easier than those based on assumptions. Be proactive, not reactive.

Electronic Valve Performance Comparison

This chart compares the performance of three different electronic valves based on key metrics such as flow rate, pressure loss, response time, and durability. Understanding these metrics is essential to selecting the right valve for your system needs.

Related Posts

-

What is an Electronic Valve and How Does it Work in Modern Systems

-

Understanding the Importance of Relief Valves in Modern Industrial Applications

-

Top 10 Hydrogen Valves for Optimal Performance and Safety in Applications

-

Unlocking the Efficiency of Cryogenic Solenoid Valves: A Deep Dive into Their Applications and Performance Data

-

Top 10 Tips for Choosing the Right Check Valve for Your Project

-

What is a Pressure Control Valve and How Does It Work in Different Applications