How to Choose the Right Air Valve for Your Pneumatic System Needs

Choosing the right air valve for your pneumatic system is a critical decision that can significantly impact efficiency, safety, and overall performance. According to a report by the International Society of Automation, the global pneumatic actuator and air valve market is expected to reach $6.5 billion by 2025, reflecting the increasing reliance on automated processes across industries. Selecting the right air valve entails understanding the specific needs of your system, including flow requirements, pressure ratings, and compatibility with other components.

Renowned industry expert Dr. Emily Chen, a leading figure in pneumatic technology, emphasizes the importance of proper selection: "The right air valve not only enhances system performance but also minimizes downtime and maintenance costs." With a variety of types such as solenoid, rotary, and proportional valves available, the decision-making process can be complex. Addressing these challenges requires a strategic approach that aligns technical specifications with operational demands, ensuring every aspect of the pneumatic system operates smoothly and effectively.

Understanding Different Types of Air Valves and Their Applications

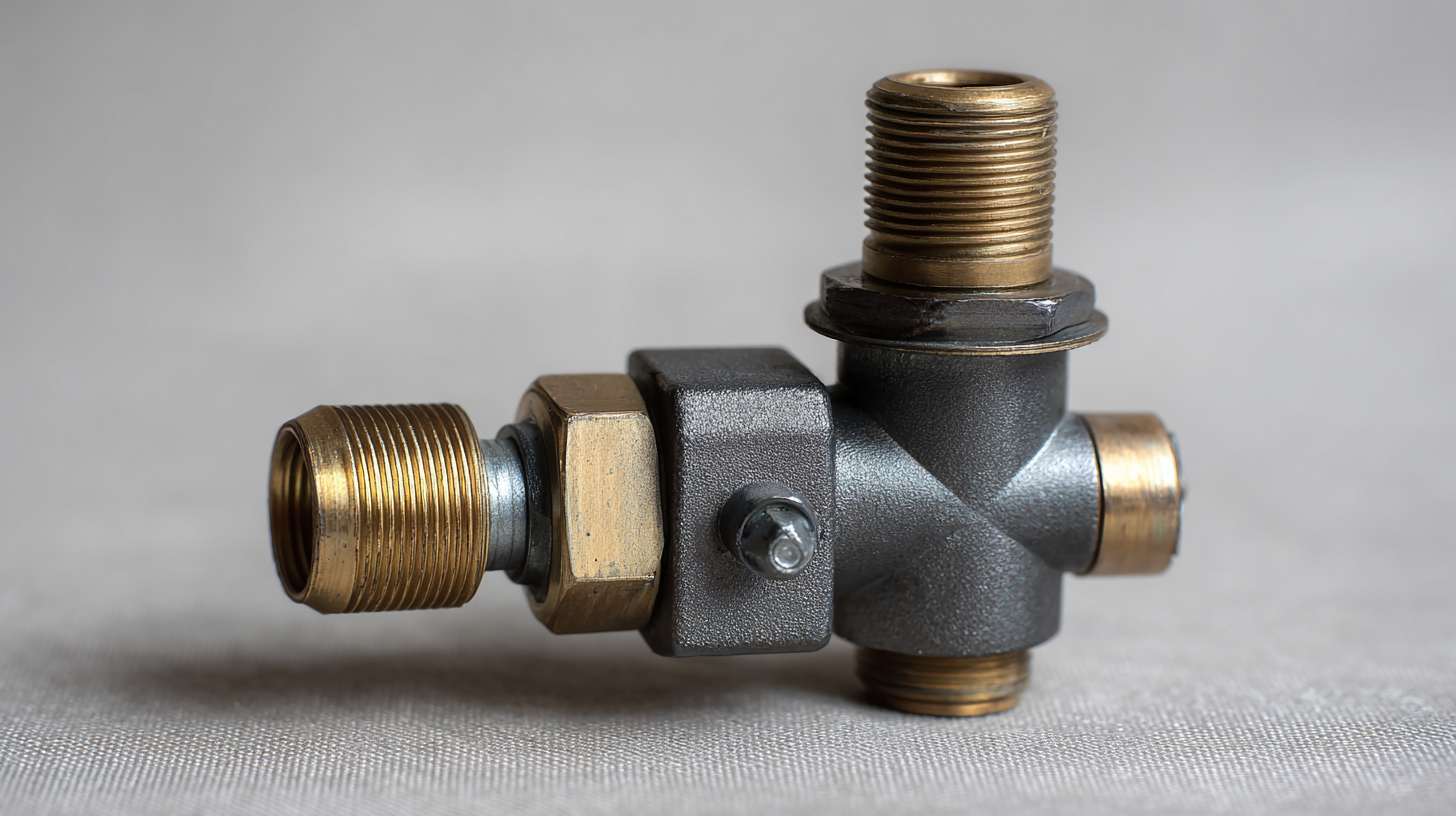

When selecting the appropriate air valve for your pneumatic system, it's essential to understand the various types available and their specific applications. One common type is the solenoid valve, which is electrically operated and ideal for automatically controlling air flow in systems requiring rapid actuation. These valves are often used in automation processes, ensuring precision and reliability in tasks such as assembly line operations and robotic applications.

Another significant category is the pneumatic control valve, which allows for manual adjustment of airflow and pressure within the system. These valves are particularly useful in applications that require fine-tuning of operating conditions, such as in pneumatic conveying systems or in industries where precise control is crucial. Additionally, there are check valves, which are designed to prevent backflow, ensuring the efficiency and safety of pneumatic systems by maintaining the correct flow direction. Understanding these different types of air valves and their specific functionalities will enable you to make an informed decision that meets your system's unique demands.

Key Factors to Consider When Selecting an Air Valve

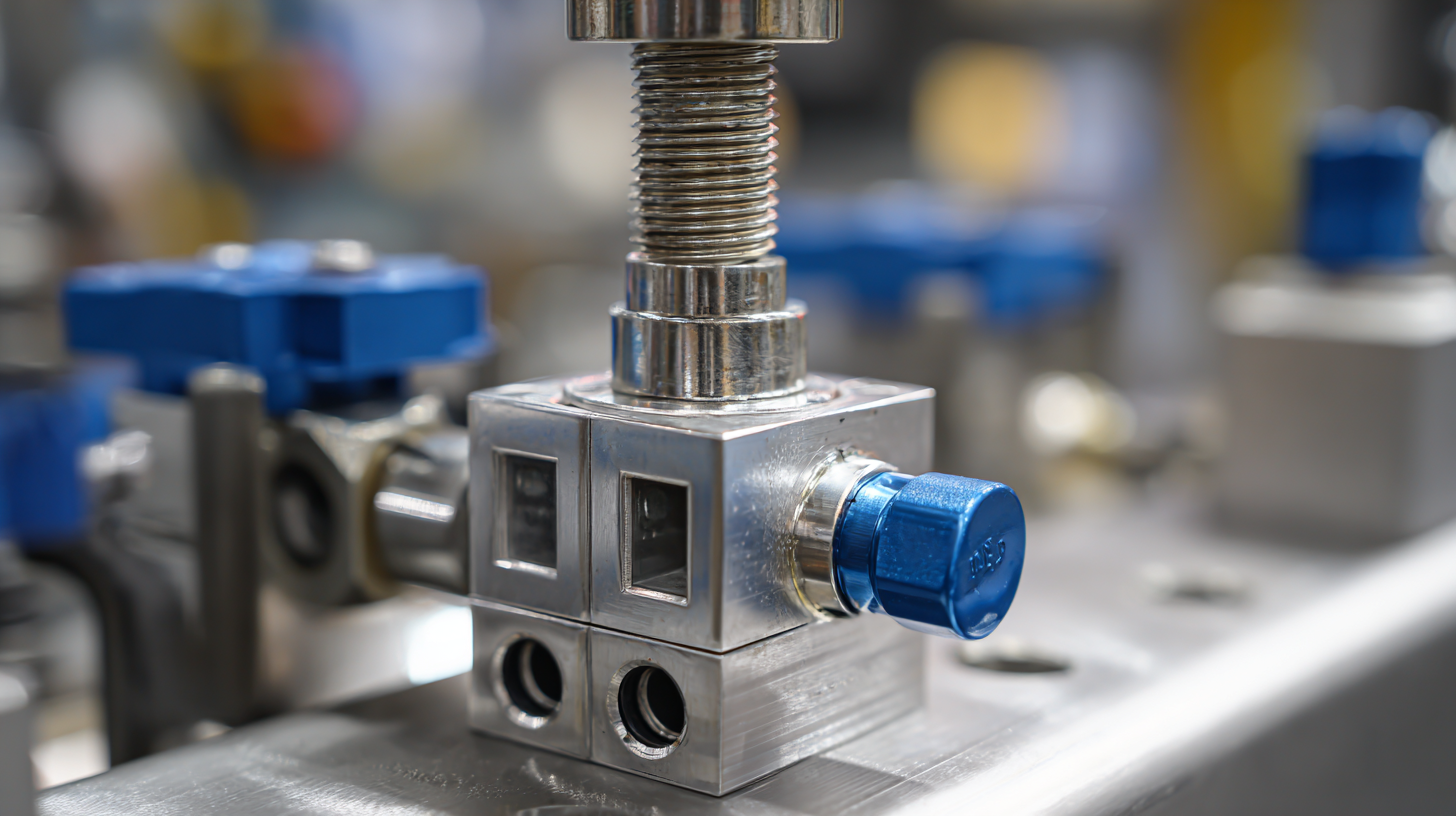

When selecting an air valve for your pneumatic system, several key factors should be taken into account to ensure optimal performance and compatibility with your specific needs. First, consider the operational pressure and flow rate requirements of your system. The air valve must be capable of handling the pressures involved without risk of failure, while also providing sufficient flow to maintain system efficiency. Additionally, assessing the type of actuation you require, whether manual, electrical, or pneumatic, will help narrow down your options.

Another important aspect is the material and design of the air valve, as these can significantly affect durability and maintenance needs. For environments that expose the valve to harsh conditions, choosing a valve made from corrosion-resistant materials will enhance longevity. Furthermore, evaluating the control precision and responsiveness needed for your application is crucial. By carefully considering these factors, you can select the right air valve that not only aligns with your system requirements but also enhances overall productivity and reliability.

Evaluating Flow Requirements for Your Pneumatic System

In pneumatic systems, choosing the right air valve can significantly impact the efficiency and effectiveness of your operations. One of the foremost considerations while selecting an air valve is evaluating the flow requirements of your system. Understanding how much air flow your application demands helps to ensure that the valve can handle the necessary pressure and volume, preventing any operational inefficiencies.

Tips:

1. Start by assessing the application needs: Determine the required flow rate and pressure levels. Consult with system specifications to create an initial estimate.

2. Consider the valve's port size: A valve with the appropriate port size is essential for optimal flow. Oversized or undersized ports can lead to leaks or insufficient flow, ultimately affecting system performance.

3. Evaluate valve response time: In applications where speed is critical, select a valve that offers quick actuation. This ensures that your pneumatic system responds promptly to operational demands.

By paying close attention to flow requirements and keeping these tips in mind, you can select an air valve that best meets your pneumatic system needs.

Assessing Pressure Ratings and Environmental Conditions

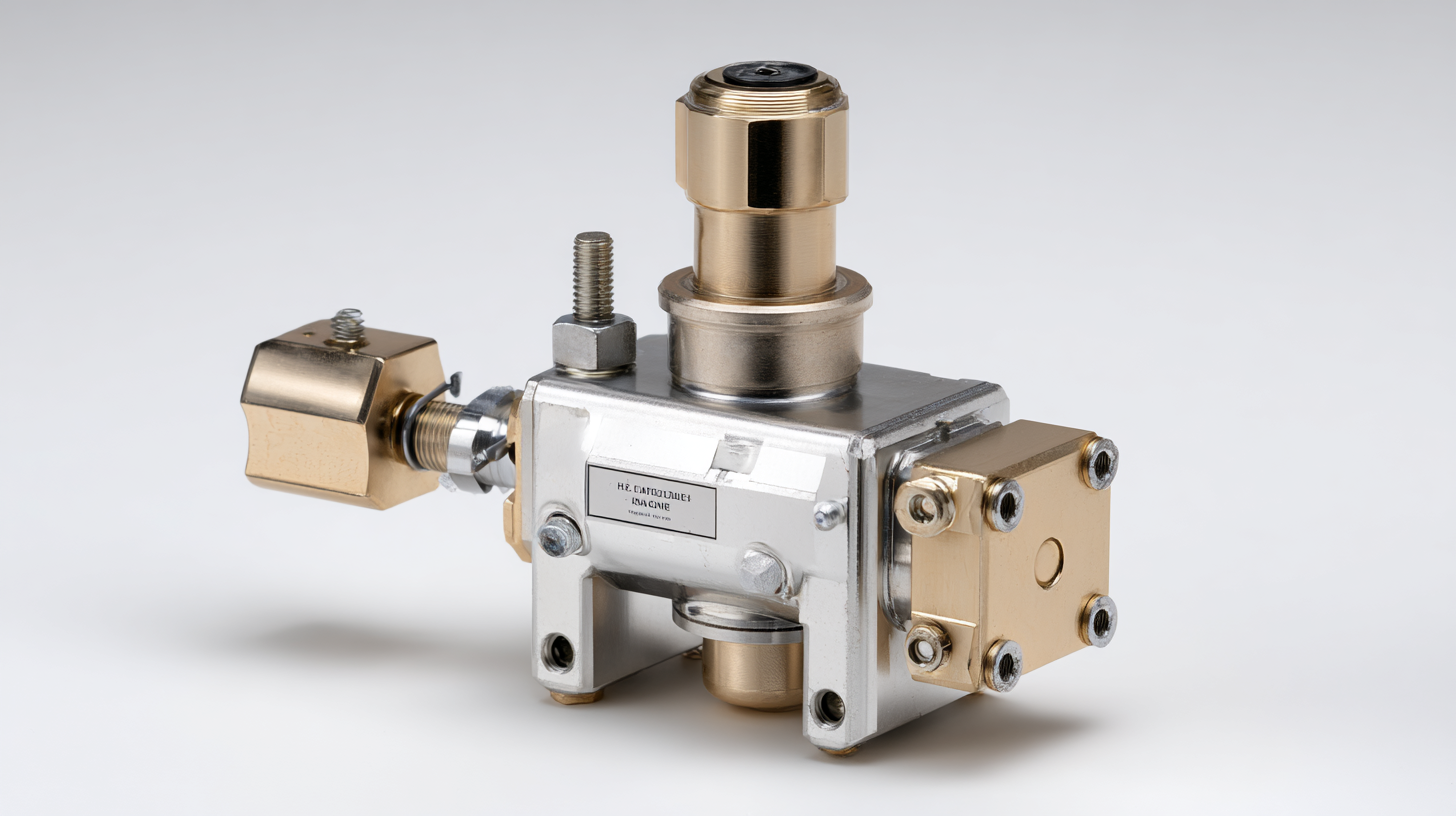

When selecting the appropriate air valve for your pneumatic system, assessing pressure ratings is crucial. Each pneumatic application has specific pressure requirements, and choosing a valve that can withstand these conditions ensures optimal functionality. Valves are typically rated for maximum working pressures, and exceeding this threshold can lead to failure, compromising system efficiency and safety. It's essential to match the valve's pressure rating with your system's specifications and to consider potential pressure fluctuations during operation.

Additionally, environmental conditions significantly impact valve performance and durability. Factors such as temperature extremes, humidity, and exposure to corrosive substances can affect the material selection and overall design of the valve. For instance, valves positioned in outdoor environments may require materials that resist rust and wear, while high-temperature applications might need valves constructed from special heat-resistant alloys. Evaluating these environmental aspects will help in choosing a valve that not only meets performance needs but also has a longer operational lifespan, thereby reducing maintenance costs over time.

Maintenance and Durability Features to Look for in Air Valves

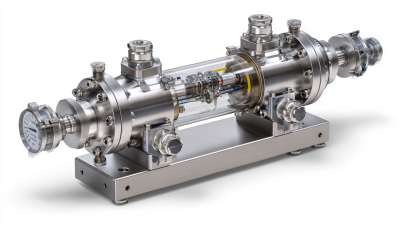

When selecting air valves for pneumatic systems, maintenance and durability are critical factors that should not be overlooked. According to a study by the International Fluid Power Society, nearly 30% of pneumatic system failures can be attributed to valve malfunctions, often due to inadequate maintenance. Thus, investing in high-quality air valves with robust materials and construction can significantly increase longevity and performance. Look for valves made from corrosion-resistant materials, such as stainless steel or anodized aluminum, to enhance resistance against environmental elements and prolong their operational lifespan.

Additionally, consider the design features that contribute to maintenance ease. Valves equipped with manual override options and clear access points for servicing can greatly reduce downtime. The Fluid Power Journal reports that simplifying maintenance processes can decrease service time by up to 40%. High-quality seals and internal components can also enhance the durability of the air valves, preventing leaks and ensuring consistent performance in demanding applications. Overall, prioritizing these maintenance and durability features will not only optimize your pneumatic system's efficiency but also offer cost savings in the long run.

Air Valve Selection Criteria for Pneumatic Systems

Related Posts

-

Understanding the Essential Role of Pressure Vacuum Valves in Modern Industrial Systems

-

Exploring the Future of Stainless Ball Valves at the 138th China Import and Export Fair 2025

-

The Essential Role of Cryogenic Valves in Modern Cryogenic Systems and Their Impact on Energy Efficiency

-

Unlocking the Science Behind Cryogenic Valves: Essential Insights for Safe Operation

-

Understanding the Importance of Relief Valves in Modern Industrial Applications

-

Understanding the Key Benefits of Using Ball Valves in Modern Plumbing Systems