Why You Need a Check Valve for Your Plumbing System to Prevent Backflow Issues

In the realm of plumbing, ensuring a seamless flow of water is crucial for maintaining both the integrity of the system and the safety of potable water. One of the most essential components in achieving this is the check valve. Renowned plumbing expert Dr. Emily Carter states, “A check valve is your first line of defense against backflow issues, preventing contamination and ensuring that your water supply remains clean and safe.”

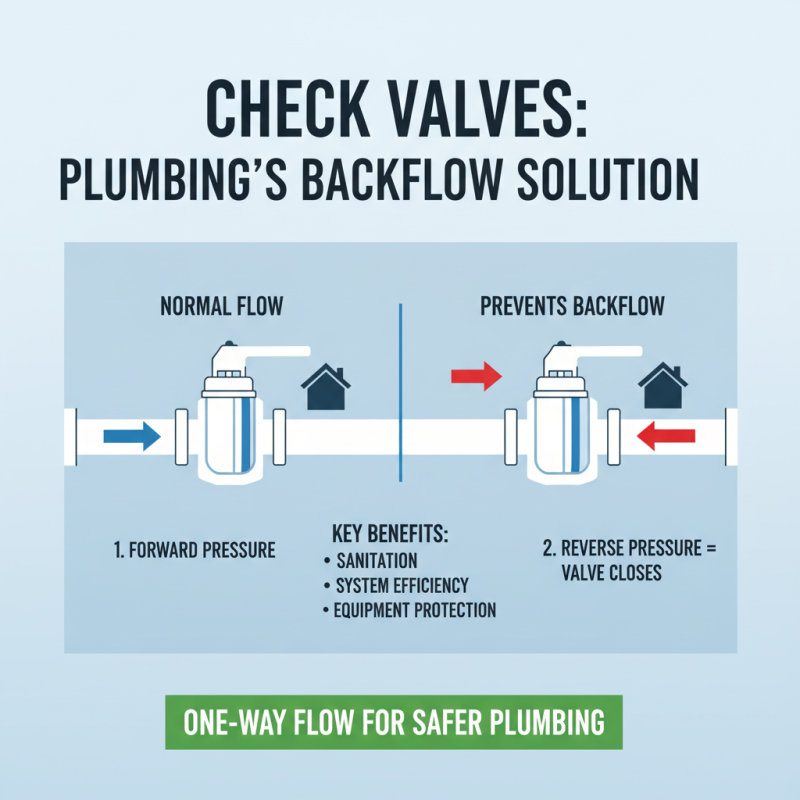

Backflow can cause significant problems, leading to potential health risks and costly repairs. When water flows in reverse, it can carry harmful contaminants from drainage systems back into clean water supplies. This is why implementing a check valve in your plumbing system is not just a precaution but a necessity. A check valve serves as a safeguard, allowing water to flow in one direction while preventing any undesirable reverse flow.

Incorporating a check valve into your plumbing setup is a proactive step to protect your home and community. Understanding the importance of this crucial device can empower homeowners and plumbers alike to take measures that ensure safe and reliable plumbing systems. As Dr. Carter emphasizes, the simplicity of the check valve belies its significance in combatting backflow and maintaining a safe water supply.

Understanding the Basics of Backflow in Plumbing Systems

Backflow in plumbing systems is a critical concern that can lead to contamination of potable water supplies, posing health risks to consumers. According to the American Water Works Association, more than 20% of public drinking water systems reported incidents of backflow, highlighting the importance of understanding this phenomenon. Backflow occurs when water flows in the opposite direction due to pressure differential, often caused by events such as main breaks, extreme weather conditions, or changes in water use patterns. This unintended reversal can allow contaminants from non-potable sources, such as irrigation systems or industrial operations, to infiltrate clean water lines, resulting in significant public health hazards.

To prevent such occurrences, the installation of check valves in plumbing systems is essential. Check valves act as one-way gates, allowing water to flow in only one direction. The Plumbing Manufacturers International reports that effective backflow prevention can reduce the risk of contamination by up to 80%, making it a vital component of any plumbing system.

Regular maintenance and testing of these devices are crucial to ensure their proper functionality, as even minor failures can lead to catastrophic results. Therefore, understanding the mechanics of backflow, along with implementing reliable preventive measures like check valves, is fundamental to maintaining the integrity of our water supplies and safeguarding public health.

The Role of Check Valves in Preventing Backflow Issues

Check valves play a crucial role in plumbing systems by preventing backflow, which can lead to significant sanitation issues and system inefficiencies. A check valve allows fluid to flow in one direction while automatically closing to prevent reverse flow when the pressure changes. This mechanism is essential in many applications, from residential plumbing to industrial systems, where maintaining the integrity of the water supply is paramount.

When backflow occurs, contaminants can enter the clean water supply, leading to potential health hazards. Check valves act as a barrier, ensuring that any pressure fluctuations do not permit water—and its associated pollutants—from flowing backward into the system. By effectively managing this aspect, check valves help maintain water quality, protect equipment, and ensure the overall reliability of a plumbing system. Their presence is essential for anyone looking to safeguard their plumbing infrastructure against backflow issues, making them a vital component in modern plumbing design.

Types of Check Valves and Their Applications in Plumbing

In plumbing systems, check valves play a crucial role in preventing backflow, ensuring water flows in one direction. There are several types of check valves, each suited for different applications. The most common types include swing check valves, which utilize a hinged disk that opens with forward flow and closes to prevent reverse flow; ball check valves, featuring a ball that seals the flow path; and diaphragm check valves, which use a flexible diaphragm to maintain sealing integrity in varying pressure conditions.

When selecting the right check valve, consider the specific requirements of your plumbing system. For example, swing check valves are ideal for applications with high flow rates, while ball check valves are excellent for managing lower flow applications due to their tight sealing capabilities. Diaphragm check valves are highly efficient in systems where pressure fluctuations are common, ensuring reliable operation.

Tip: Always ensure that the chosen check valve is compatible with the fluid type in your plumbing system to maintain optimal performance. Regular maintenance of check valves can prevent malfunctions that may lead to backflow issues, so be sure to inspect them regularly for any signs of wear or damage. Additionally, consider the installation location, as mounting orientation can affect the efficacy of certain valve types.

Signs Your Plumbing System Needs a Check Valve

A check valve is an essential component in plumbing systems, serving as a preventative measure against backflow, which can lead to various plumbing issues. Identifying the signs that your plumbing system needs a check valve is crucial for maintaining water quality and system efficiency. According to the Environmental Protection Agency (EPA), backflow can pose serious health risks, contaminating drinking water with pollutants. If you notice discolored water or a foul smell emanating from your fixtures, these could be indications that backflow is occurring and a check valve might be necessary.

Another significant sign to look for is fluctuating water pressure during usage. A sudden drop in pressure may signal that water is flowing in the wrong direction, potentially causing contamination. The American Society of Plumbing Engineers (ASPE) reports that proper installation of check valves in residential and commercial plumbing can effectively prevent such scenarios. Additionally, if you encounter frequent clogs in your drains or sewer lines, this could indicate that backflow is causing debris to travel upstream, another situation where a check valve could mitigate the problem. Recognizing these signs early can save homeowners from costly repairs and health hazards associated with contaminated water supplies.

Why You Need a Check Valve for Your Plumbing System to Prevent Backflow Issues

Maintenance Tips for Keeping Check Valves Functioning Properly

Regular maintenance is essential to keep check valves functioning effectively in your plumbing system. One important aspect of maintenance is the periodic inspection of the valves for any signs of wear or damage. This should include checking for leaks, corrosion, or any blockage that could hinder the valve's operation. It is advisable to schedule these inspections at least once a year to ensure that the valves are operating at optimal efficiency. Additionally, cleaning any debris or buildup around the valve can help prevent malfunctions.

Another vital maintenance tip is to ensure that the check valves are properly aligned and securely mounted. Misalignment can cause improper sealing, leading to backflow issues and potential water damage. If you notice any misalignment, it is important to readjust the valve or consult a plumbing professional for assistance. Furthermore, testing the valves' effectiveness by running water through the system occasionally is a good practice. This will help you determine if the valves are functioning as intended, allowing for prompt repairs if needed before significant issues arise.

Related Posts

-

The Ultimate Guide to Choosing the Right Flow Check Valve for Your System Needs

-

Top 10 Benefits of Using Flow Check Valves in Your Plumbing System

-

Top 10 Check Valve Types for Optimal Flow Control and Industry Applications

-

How to Choose the Right Air Valve for Your Pneumatic System Needs

-

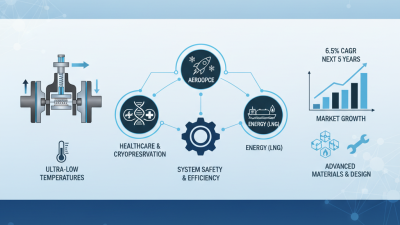

The Essential Role of Cryogenic Valves in Modern Cryogenic Systems and Their Impact on Energy Efficiency

-

Best Cryogenic Check Valves for Essential Applications in Cold Environments